BS5308 Part 2 / Type 1 unarmoured instrumentation cables

BS5308 Cable Part 2 Type 1 PVC-OS-PVC and a BS5308 Cable Part 2 Type 1 PVC-IS-OS-PVC unarmoured versions are generally use for indoor installation and suitable for wet and damp areas. Generally used within industrial process manufacturing plants for communication, data and voice transmission signals and services, Also used for the interconnection of electrical equipment and instruments, typically in chemical or petrolchemical industry.

Cable-uni Instrumentation cables manufactured in accordance with British Standard BS5308, include BS5308 Part 2 Type 1 - Unarmoured construction - PVC insulated and PVC oversheathed.Cable-uni's own factory-produced instrumentation cables are sold at ex-works prices.

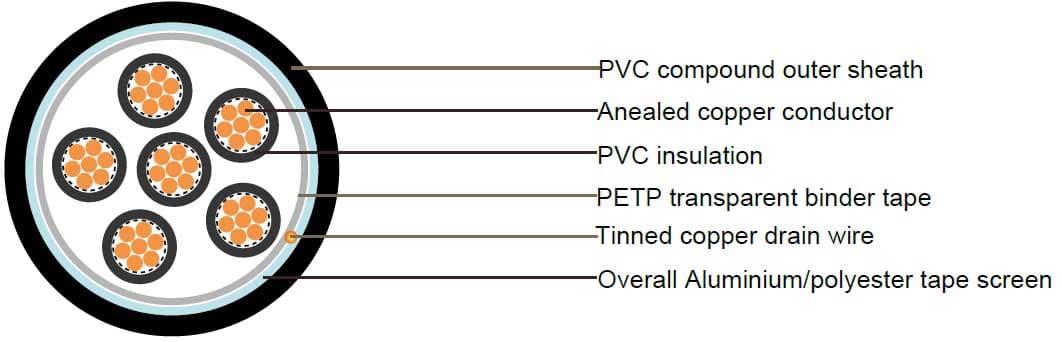

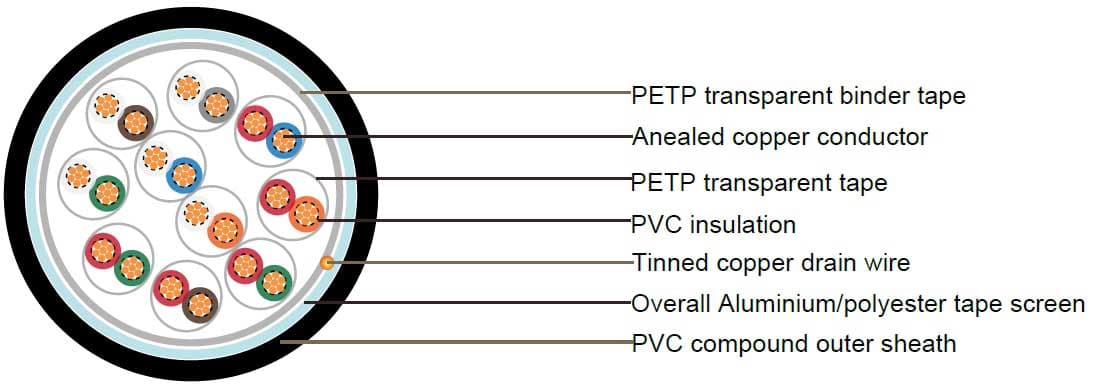

BS5308 Cable Part 2 Type 1 PVC-OS-PVC

Multicore

Multipair

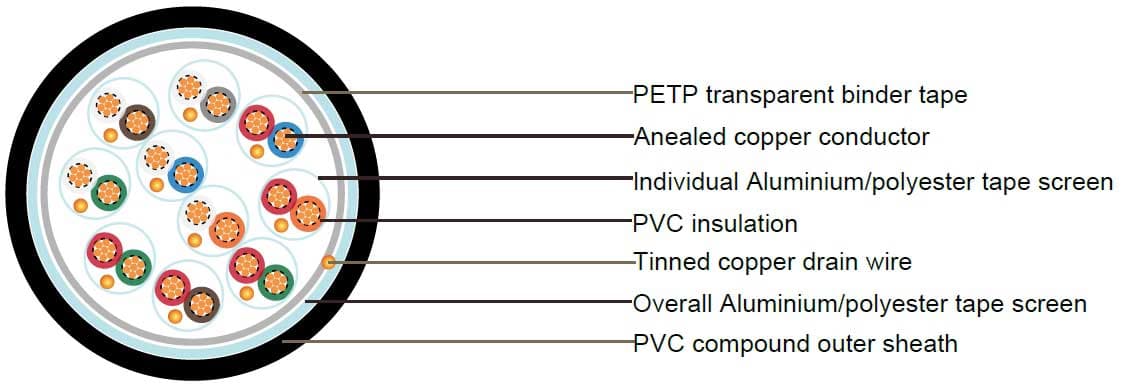

BS5308 Cable Part 2 Type 1 PVC-IS-OS-PVC

Parameter

BS5308 Cable Part 2 Type 1 PVC-IS-OS-PVC

| No.of Cores | No.and Dia. of Wires | Nominal Conductor Cross-Sectional Area | Nominal Thickness of Insulation | Nominal Thickness of Sheath | Nominal Dia. of Cable | Approx. Weight |

| no./mm | mm2 | mm | mm | mm | kg/km | |

| 2 | 16/0.2 | 0.5 | 0.6 | 1.1 | 11.2 | 170 |

| 5 | 16/0.2 | 0.5 | 0.6 | 1.2 | 14.6 | 270 |

| 10 | 16/0.2 | 0.5 | 0.6 | 1.3 | 19.4 | 520 |

| 15 | 16/0.2 | 0.5 | 0.6 | 15 | 22.7 | 650 |

| 20 | 16/0.2 | 0.5 | 0.6 | 1.5 | 25.9 | 860 |

| 30 | 16/0.2 | 0.5 | 0.6 | 1.7 | 31.2 | 1130 |

| 50 | 16/0.2 | 0.5 | 0.6 | 2.2 | 40.1 | 1880 |

| 2 | 24/0.2 | 0.75 | 0.6 | 1.1 | 12.2 | 200 |

| 5 | 24/0.2 | 0.75 | 0.6 | 1.2 | 15.8 | 355 |

| 10 | 24/0.2 | 0.75 | 0.6 | 1.3 | 21.1 | 560 |

| 15 | 24/0.2 | 0.75 | 0.6 | 1.5 | 24.9 | 770 |

| 20 | 24/0.2 | 0.75 | 0.6 | 1.7 | 28.6 | 990 |

| 30 | 24/0.2 | 0.75 | 0.6 | 2 | 34.7 | 1380 |

| 50 | 24/0.2 | 0.75 | 0.6 | 2.2 | 43.9 | 2225 |

| 2 | 7/0.53 | 1.5 | 0.6 | 1.2 | 13.6 | 265 |

| 5 | 7/0.53 | 1.5 | 0.6 | 1.3 | 147.8 | 490 |

| 10 | 7/0.53 | 1.5 | 0.6 | 1.5 | 24.1 | 820 |

| 15 | 7/0.53 | 1.5 | 0.6 | 1.7 | 28.2 | 1110 |

| 20 | 7/0.53 | 1.5 | 0.6 | 1.7 | 31.9 | 1470 |

| 30 | 7/0.53 | 1.5 | 0.6 | 2 | 38.8 | 2070 |

| 50 | 7/0.53 | 1.5 | 0.6 | 2.2 | 49.1 | 3340 |

Multicore

| No.of Cores | No.and Dia. of Wires | Nominal Conductor Cross-Sectional Area | Nominal Thickness of Insulation | Nominal Thickness of Sheath | Nominal Dia. of Cable | Approx. Weight |

| no./mm | mm2 | mm | mm | mm | kg/km | |

| 2 | 16/0.2 | 0.5 | 0.6 | 0.8 | 6.2 | 60 |

| 3 | 16/0.2 | 0.5 | 0.6 | 0.8 | 6.6 | 75 |

| 4 | 16/0.2 | 0.5 | 0.6 | 0.8 | 7.2 | 80 |

| 6 | 16/0.2 | 0.5 | 0.6 | 0.9 | 8.6 | 110 |

| 10 | 16/0.2 | 0.5 | 0.6 | 1.1 | 11.2 | 180 |

| 20 | 16/0.2 | 0.5 | 0.6 | 1.2 | 14.2 | 310 |

| 40 | 16/0.2 | 0.5 | 0.6 | 1.3 | 18.7 | 570 |

| 80 | 16/0.2 | 0.5 | 0.6 | 1.5 | 26.5 | 1080 |

| 2 | 24/0.2 | 0.75 | 0.6 | 0.8 | 6.7 | 75 |

| 3 | 24/0.2 | 0.75 | 0.6 | 0.8 | 7.2 | 90 |

| 4 | 24/0.2 | 0.75 | 0.6 | 0.8 | 7.8 | 100 |

| 6 | 24/0.2 | 0.75 | 0.6 | 0.9 | 9.4 | 140 |

| 10 | 24/0.2 | 0.75 | 0.6 | 1.1 | 12.2 | 220 |

| 20 | 24/0.2 | 0.75 | 0.6 | 1.2 | 15.6 | 390 |

| 40 | 24/0.2 | 0.75 | 0.6 | 1.3 | 20.6 | 710 |

| 80 | 24/0.2 | 0.75 | 0.6 | 1.5 | 28.5 | 1350 |

| 2 | 7/0.53 | 1.5 | 0.6 | 0.8 | 8 | 105 |

| 3 | 7/0.53 | 1.5 | 0.6 | 0.9 | 8.2 | 135 |

| 4 | 7/0.53 | 1.5 | 0.6 | 0.9 | 9 | 150 |

| 6 | 7/0.53 | 1.5 | 0.6 | 1.1 | 11 | 205 |

| 10 | 7/0.53 | 1.5 | 0.6 | 1.2 | 14 | 330 |

| 20 | 7/0.53 | 1.5 | 0.6 | 1.3 | 17.9 | 580 |

| 40 | 7/0.53 | 1.5 | 0.6 | 1.5 | 24 | 1065 |

| 80 | 7/0.53 | 1.5 | 0.6 | 1.7 | 32.9 | 2025 |

| No.of Cores | No.and Dia. of Wires | Nominal Conductor Cross-Sectional Area | Nominal Thickness of Insulation | Nominal Thickness of Sheath | Nominal Dia. of Cable | Approx. Weight |

| no./mm | mm2 | mm | mm | mm | kg/km | |

| 1 | 16/0.2 | 0.5 | 0.6 | 0.8 | 6.2 | 60 |

| 2 | 16/0.2 | 0.5 | 0.6 | 0.8 | 7.6 | 80 |

| 5 | 16/0.2 | 0.5 | 0.6 | 1.1 | 12.4 | 200 |

| 10 | 16/0.2 | 0.5 | 0.6 | 1.2 | 16.5 | 340 |

| 15 | 16/0.2 | 0.5 | 0.6 | 1.3 | 19.2 | 480 |

| 20 | 16/0.2 | 0.5 | 0.6 | 1.3 | 21.7 | 570 |

| 30 | 16/0.2 | 0.5 | 0.6 | 1.5 | 26.4 | 880 |

| 50 | 16/0.2 | 0.5 | 0.6 | 1.7 | 33.4 | 1310 |

| 1 | 24/0.2 | 0.75 | 0.6 | 0.8 | 6.7 | 75 |

| 2 | 24/0.2 | 0.75 | 0.6 | 0.8 | 8.2 | 100 |

| 5 | 24/0.2 | 0.75 | 0.6 | 1.2 | 13.8 | 250 |

| 10 | 24/0.2 | 0.75 | 0.6 | 1.3 | 18.4 | 450 |

| 15 | 24/0.2 | 0.75 | 0.6 | 1.3 | 21.1 | 600 |

| 20 | 24/0.2 | 0.75 | 0.6 | 1.5 | 24.4 | 800 |

| 30 | 24/0.2 | 0.75 | 0.6 | 1.7 | 29.5 | 1080 |

| 50 | 24/0.2 | 0.75 | 0.6 | 2 | 37.6 | 1860 |

| 1 | 7/0.53 | 1.5 | 0.6 | 0.8 | 7.5 | 100 |

| 2 | 7/0.53 | 1.5 | 0.6 | 0.9 | 9.3 | 150 |

| 5 | 7/0.53 | 1.5 | 0.6 | 1.2 | 15.6 | 360 |

| 10 | 7/0.53 | 1.5 | 0.6 | 1.3 | 20.9 | 670 |

| 15 | 7/0.53 | 1.5 | 0.6 | 1.5 | 24.6 | 970 |

| 20 | 7/0.53 | 1.5 | 0.6 | 1.5 | 27.8 | 1230 |

| 30 | 7/0.53 | 1.5 | 0.6 | 1.7 | 33.7 | 1730 |

| 50 | 7/0.53 | 1.5 | 0.6 | 2 | 43 | 2740 |

YPVCPiMFCable.png)