Uni-Cable's offshore and marine cables are specialized types of cables designed for use in harsh environments such as oceans, seas, and other water bodies. They are used primarily in offshore oil and gas platforms, marine renewable energy installations (such as offshore wind farms and tidal energy facilities), telecommunications, and undersea research applications.

Compliance and Certification:Uni-Cable's offshore and marine cables adhere to specific industry standards and regulations to ensure safety and performance. Certifications such as IEC 60092 (International Electrotechnical Commission) standards, NEK 606, BS 6883, BS 7917

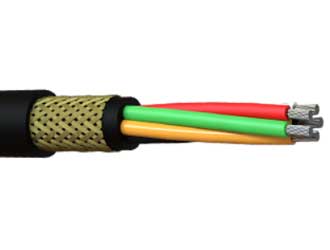

key features for Uni-Cable offshore and marine cables:Durability: Offshore and marine cables are built to withstand extreme conditions including saltwater exposure, underwater pressure, and temperature variations. They are constructed with materials that resist corrosion and degradation over time.

Water Resistance: These cables are typically waterproof and designed to prevent water ingress, which can cause electrical failures or corrosion of internal components.

Strength and Flexibility: They need to be strong and flexible to withstand installation stresses, such as being pulled through water or laid on the seabed. The cables are often armored with materials like steel wires to provide mechanical protection.

Insulation and Sheathing: Special insulation and sheathing materials are used to protect the conductors from moisture and mechanical damage. Common materials include cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) for insulation, and thermoplastic or thermoset materials for outer sheathing.

UV Resistance: Some marine cables are exposed to sunlight if they run along the seabed or are part of floating installations. UV-resistant materials are used to prevent degradation from prolonged exposure to sunlight.

Electrical Performance: Offshore and marine cables must maintain their electrical performance over long distances and undersea environments. This includes considerations for signal integrity, voltage ratings, and impedance control.

Installation Methods: Specialized installation techniques are used for laying offshore and marine cables, such as plowing, jetting, or direct burial. Submarine cable-laying vessels are employed for large-scale installations.

Application-Specific Designs: Different applications require specific cable designs. For instance, subsea power cables for offshore wind farms have different requirements compared to those used for telecommunications or seismic monitoring. Accessing and maintaining offshore and marine cables can be challenging due to their location. Design considerations often include minimizing the need for maintenance or making it feasible using specialized equipment.

The design and selection of offshore and marine cables depend heavily on the specific application, environmental conditions, installation methods, and regulatory requirements. These cables play a crucial role in supporting offshore industries and enabling connectivity in marine environments.

We have vast experience in advising on offshore and marine cables selection. Our technical team is available to discuss your application and to help you meet the specific requirements. Get a free quote by E-mail:info@cable-uni.com