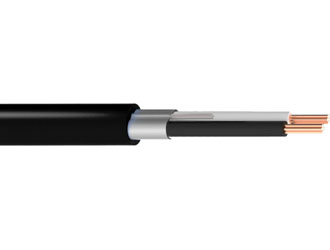

600V Instrumentation Cable

Application

For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type TC and approved for installation indoors or outdoors, aerially, in conduits, ducts, cable trays and direct burial in circuits not exceeding 600 volts. May be used in NEC Class 1, Division 2 hazardous locations. UL approved for NEC continuous operation at 75°C in wet locations, 90°C in dry locations, 130°C for emergency overload conditions, and 250°C for short circuit conditions.

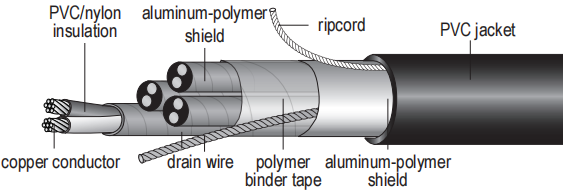

| 600 Volt UL Type TC, 90°C; Multiple Pairs; Overall Shield; TFN PVC/Nylon Insulation & PVC Jacket; Copper Conductors |  |

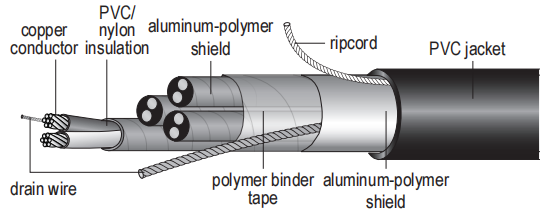

| 600 Volt UL Type TC, 90°C; Single & Multiple Twisted Pairs; Individual & Overall Shield; TFN PVC/Nylon Insulation & PVC Jacket; Copper Conductors |  |

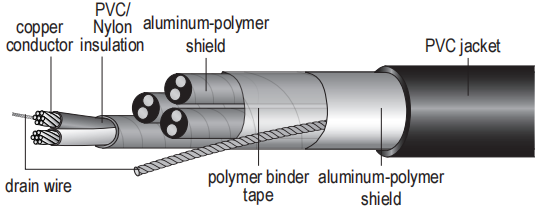

| 600 Volt UL Type TC, 90°C; Multiple Pairs; Individual & Overall Shield; THHN or THWN Insulation & PVC Jacket; Copper Conductors |  |

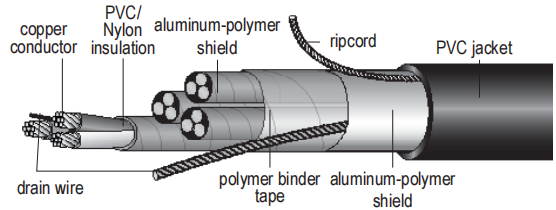

| 600 Volt UL Type TC-ER, 90°C; Single and Multiple Triads; Individual & Overall Shield; TFN PVC/Nylon Insulation & PVC Jacket; Copper Conductors |  |

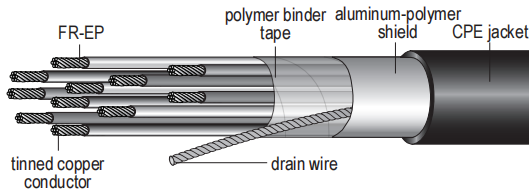

| 600 Volt UL Type TC, 90°C; Multiple Conductor; Overall Shield; FR-EP Insulation & CPE Jacket; Tinned Copper Conductors, Flame-retardant Instrumentation cable |  |

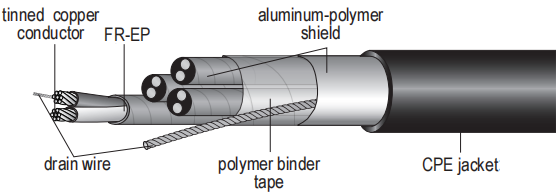

| 600 Volt UL Type TC-ER, 90°C; Multiple Pairs; Individual & Overall Shield; FR-EP Insulation & CPE Jacket; Tinned Copper Conductors, Flame-retardant Instrumentation cable |  |

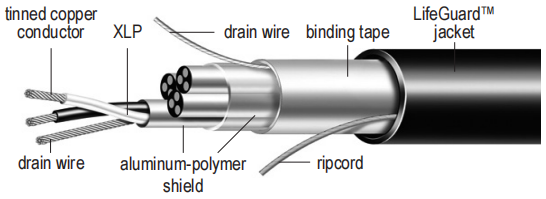

| 600 Volt UL Type TC-LS, 90°C; Single & Multiple Pairs; Individual & Overall Shield; XLP Insulation; Low Smoke Zero Halogen Jacket; Tinned Copper Conductors FM Approved, Low Smoke Zero Halogen Instrumentation cable |  |

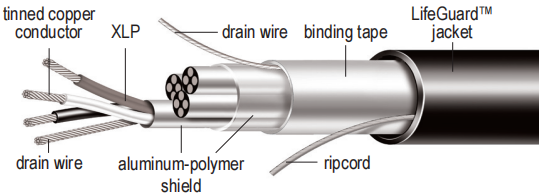

| 600 Volt UL Type TC-LS, 90°C; Single & Multiple Triads; Individual & Overall Shield; XLP Insulation; Low Smoke Zero Halogen Jacket; Tinned Copper Conductors; FM Approved, Low Smoke Zero Halogen Instrumentation cable |  |

600V Multiple Pairs - TFN PVC/Nylon, PVC, O/S

| Size AWG | Number of Pairs | Insulation Thickness Mils | Nylon Covering Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 18 | 2 | 15 | 4 | 45 | 0.41 | 70 |

| 18 | 4 | 15 | 4 | 45 | 0.49 | 118 |

| 18 | 8 | 15 | 4 | 60 | 0.65 | 212 |

| 18 | 12 | 15 | 4 | 60 | 0.76 | 302 |

| 18 | 16 | 15 | 4 | 80 | 0.89 | 374 |

| 18 | 24 | 15 | 4 | 80 | 1.03 | 572 |

| 18 | 36 | 15 | 4 | 80 | 1.18 | 796 |

| 18 | 50 | 15 | 4 | 80 | 1.44 | 1046 |

| 16 | 2 | 15 | 4 | 45 | 0.45 | 89 |

| 16 | 3 | 15 | 4 | 45 | 0.52 | 121 |

| 16 | 4 | 15 | 4 | 45 | 0.57 | 150 |

| 16 | 8 | 15 | 4 | 60 | 0.75 | 283 |

| 16 | 12 | 15 | 4 | 60 | 0.88 | 389 |

| 16 | 16 | 15 | 4 | 80 | 1.03 | 540 |

| 16 | 24 | 15 | 4 | 80 | 1.21 | 742 |

| 16 | 36 | 15 | 4 | 80 | 1.4 | 1038 |

| 16 | 50 | 15 | 4 | 80 | 1.61 | 1436 |

600V Single & Multiple Twisted Pairs - TFN PVC/Nylon, PVC, I/S & O/S

| Size AWG | Number of Pairs | Insulation Thickness Mils | Nylon Covering Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 18 | 1 | 15 | 4 | 45 | 0.27 | 42 |

| 18 | 2 | 15 | 4 | 45 | 0.44 | 82 |

| 18 | 4 | 15 | 4 | 45 | 0.52 | 146 |

| 18 | 8 | 15 | 4 | 60 | 0.71 | 279 |

| 18 | 12 | 15 | 4 | 60 | 0.85 | 391 |

| 18 | 16 | 15 | 4 | 80 | 1.05 | 494 |

| 18 | 24 | 15 | 4 | 80 | 1.2 | 752 |

| 18 | 36 | 15 | 4 | 80 | 1.37 | 1053 |

| 18 | 50 | 15 | 4 | 80 | 1.71 | 1300 |

| 16 | 1 | 15 | 4 | 45 | 0.29 | 55 |

| 16 | 2 | 15 | 4 | 45 | 0.48 | 105 |

| 16 | 3 | 15 | 4 | 45 | 0.56 | 136 |

| 16 | 4 | 15 | 4 | 60 | 0.63 | 207 |

| 16 | 6 | 15 | 4 | 60 | 0.77 | 257 |

| 16 | 8 | 15 | 4 | 60 | 0.81 | 349 |

| 16 | 12 | 15 | 4 | 80 | 1.11 | 528 |

| 16 | 16 | 15 | 4 | 80 | 1.16 | 623 |

| 16 | 24 | 15 | 4 | 80 | 1.39 | 944 |

| 16 | 36 | 15 | 4 | 80 | 1.59 | 1331 |

| 16 | 50 | 15 | 4 | 110 | 1.96 | 1731 |

600V Multiple Pairs - THHN PVC/Nylon, PVC, I/S & O/S

| Size AWG | Number of Pairs | Insulation Thickness Mils | Nylon Covering Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 14 | 2 | 15 | 4 | 45 | 0.57 | 156 |

| 14 | 4 | 15 | 4 | 60 | 0.73 | 285 |

| 14 | 8 | 15 | 4 | 60 | 0.93 | 520 |

| 14 | 12 | 15 | 4 | 80 | 1.16 | 788 |

| 14 | 16 | 15 | 4 | 80 | ||

| 14 | 24 | 15 | 4 | 80 | 1.58 | 1445 |

600V Multiple Triads - TFN PVC/Nylon, PVC, I/S & O/S

| Size AWG | Number of Triads | Insulation Thickness Mils | Nylon Covering Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 18 | 1 | 15 | 4 | 45 | 0.29 | 52 |

| 18 | 4 | 15 | 4 | 60 | 0.61 | 207 |

| 18 | 8 | 15 | 4 | 60 | 0.78 | 355 |

| 18 | 12 | 15 | 4 | 80 | 0.98 | 538 |

| 18 | 24 | 15 | 4 | 80 | 1.33 | 971 |

| 16 | 1 | 15 | 4 | 45 | 0.31 | 55 |

| 16 | 4 | 15 | 4 | 60 | 0.67 | 233 |

| 16 | 8 | 15 | 4 | 60 | 0.9 | 401 |

| 16 | 12 | 15 | 4 | 80 | 1.08 | 607 |

| 16 | 16 | 15 | 4 | 80 | 1.27 | 838 |

| 16 | 24 | 15 | 4 | 80 | 1.48 | 1100 |

600V Multiple Conductor - FR-EP, CPE, O/S

| Size AWG | Number of Conductors | Insulation Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 18 | 2 | 25 | 45 | 0.3 | 42 |

| 18 | 3 | 25 | 45 | 0.31 | 53 |

| 16 | 2 | 25 | 45 | 0.32 | 52 |

| 16 | 3 | 25 | 45 | 0.34 | 66 |

| 16 | 4 | 25 | 45 | 0.37 | 80 |

600V Multiple Pairs or Triads - FR-EP, CPE, I/S & O/S

| Size AWG | Number of Pairs | Insulation Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 18 | 2 | 25 | 45 | 0.48 | 90 |

| 18 | 4 | 25 | 60 | 0.59 | 165 |

| 18 | 8 | 25 | 60 | 0.75 | 280 |

| 18 | 12 | 25 | 80 | 0.93 | 430 |

| 18 | 16 | 25 | 80 | 1.05 | 540 |

| 18 | 24 | 25 | 80 | 1.24 | 760 |

600V Single or Multiple Pairs - XLP, LSZH, I/S & O/S

| Size AWG | Number of Pairs | Insulation Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 16 | 1 | 30 | 60 | 0.33 | 59 |

| 16 | 2 | 30 | 60 | 0.58 | 136 |

| 16 | 4 | 30 | 60 | 0.67 | 216 |

| 16 | 8 | 30 | 60 | 0.9 | 397 |

| 16 | 12 | 30 | 80 | 1.04 | 530 |

| 16 | 24 | 30 | 80 | 1.4 | 960 |

600V Single or Multiple Triads - XLP, LSZH, I/S & O/S

| Size AWG | Number of Triads | Insulation Thickness Mils | Jacket Thickness Mils | Overall Diameter Inches | Net Weight Lbs/Mft |

| 16 | 1 | 30 | 60 | 0.35 | 67 |

| 16 | 2 | 30 | 60 | 0.64 | 170 |

| 16 | 4 | 30 | 60 | 0.74 | 268 |

| 16 | 6 | 30 | 60 | 0.93 | 422 |

| 16 | 8 | 30 | 80 | 0.96 | 500 |

| 16 | 12 | 30 | 80 | 1.14 | 705 |

We have vast experience in advising on Instrumentation cable selection. Our technical team is available to discuss your application and to help you meet the specific requirements.Get a free quote by E-mail:info@cable-uni.com

YSWAYPVCCable.png)