TACSR TACSR/AW Conductor Overview

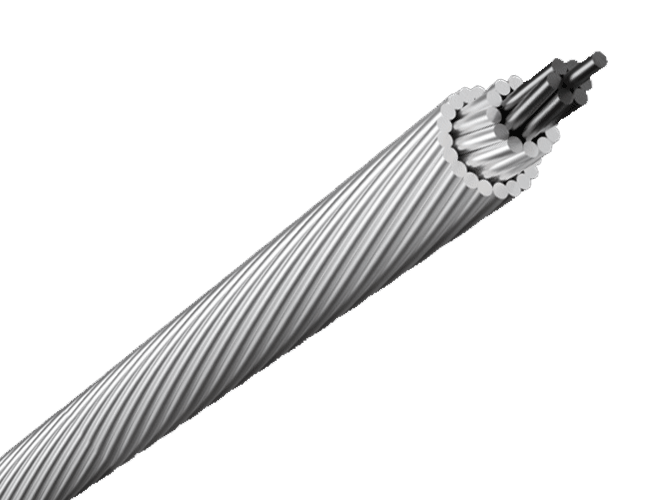

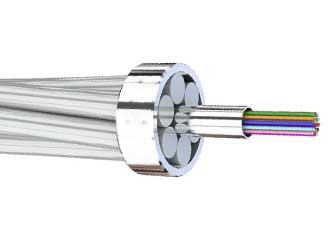

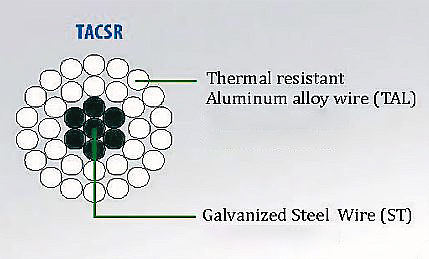

TACSR (Thermal Resistant Aluminum Conductor Steel Reinforced) and TACSR/AW (Thermal Resistant Aluminum Conductor Steel Reinforced with Aluminum Clad Steel) are high-temperature aluminum conductors designed for overhead power transmission lines. With their heat-resistant aluminum alloy composition, these conductors provide low-sag performance, high conductivity, and enhanced mechanical strength, making them ideal for smart grid infrastructure and renewable energy projects.

TACSR and TACSR/AW conductors offer superior sag-tension control, high-strength aluminum conductor properties, and corrosion resistance, making them excellent alternatives to traditional ACSR and ACSS conductors for energy-efficient power transmission.

TACSR & TACSR/AW Conductors Applications

Overhead transmission line aluminum conductor

High-voltage power transmission networks

Renewable energy projects (wind & solar power integration)

Smart grid aluminum conductor solutions

Industrial and urban electrical distribution systems

TACSR TACSR/AW Conductor Technical Specifications

Material: Heat-resistant aluminum alloy with steel core

Reinforcement: Galvanized steel (TACSR) or aluminum-clad steel (TACSR/AW)

Operating Temperature: High-temperature aluminum conductor (Up to 210°C)

Mechanical Strength: High-strength aluminum conductor with superior sag-tension control

Corrosion Resistance: TACSR/AW provides enhanced anti-corrosion properties

TACSR TACSR/AW Conductor Standards:

IEC 61089 – International standard for overhead electrical conductors

ASTM B856/B857 – Standard specifications for high-temperature aluminum conductors

BS EN 50182 – Conductors for overhead lines

DIN 48204 – German standard for aluminum conductors

GB/T 1179 – Chinese national standard for overhead conductors

TACSR TACSR/AW Conductor Parameters

|

Conductor Size

(mm2) |

Stranding (Nos./mm) |

Min. Breaking Load (kgf) |

Reference |

|||||||||||||

|

Cross-sectional Area (mm2) |

Overall Diameter (mm) |

Weight (kg/km) |

DC Resistance at 20℃ (Oh/km) |

Modulus of Elasticity (kgf/mm2) |

Coefficient of Linear Expansion (10-6/℃) |

Standard Length

(m) |

Current Carrying Capacity (A) |

|||||||||

|

TAl |

ST |

TAl |

ST |

Total |

TAl |

ST |

TAl |

ST |

Total |

|||||||

|

58 |

6/3.5 |

1/3.5 |

1,980 |

57.73 |

9.621 |

67.35 |

10.5 |

3.5 |

158.1 |

75.04 |

233.1 |

0.505 |

8,400 |

18.9 |

1,000 |

343 |

|

80 |

6/4.2 |

1/4.2 |

2,770 |

83.10 |

13.85 |

96.95 |

12.6 |

4.2 |

227.5 |

108.0 |

335.5 |

0.350 |

8,400 |

18.9 |

1,000 |

430 |

|

95 |

6/4.5 |

1/4.5 |

3,810 |

95.40 |

15.90 |

111.3 |

13.5 |

4.5 |

261.2 |

124.0 |

385.2 |

0.306 |

8,400 |

18.9 |

1,000 |

478 |

|

80 |

15/2.6 |

4/2.6 |

4,720 |

79.64 |

21.24 |

100.9 |

13.0 |

7.8 |

219.2 |

166.5 |

385.7 |

0.368 |

9,390 |

17.6 |

2,000 |

448 |

|

100 |

15/2.9 |

4/2.9 |

5,580 |

99.08 |

26.42 |

125.5 |

14.5 |

8.7 |

272.8 |

207.1 |

479.9 |

0.296 |

9,390 |

17.6 |

2,000 |

517 |

|

120 |

15/3.2 |

4/3.2 |

5,550 |

120.6 |

32.17 |

152.8 |

16.0 |

9.6 |

332.2 |

252.2 |

584.4 |

0.243 |

9,390 |

17.6 |

2,000 |

590 |

|

120 |

30/2.3 |

7/2.3 |

5,540 |

124.7 |

29.09 |

153.8 |

16.1 |

6.9 |

345.7 |

228.0 |

573.7 |

0.237 |

9,080 |

18.0 |

2,000 |

598 |

|

160 |

30/2.6 |

7/2.6 |

6,980 |

159.3 |

37.16 |

196.5 |

18.2 |

7.8 |

441.5 |

291.3 |

732.8 |

0.185 |

9,080 |

18.0 |

2,000 |

706 |

|

200 |

30/2.9 |

7/2.9 |

8,640 |

198.2 |

46.24 |

244.4 |

20.3 |

8.7 |

549.3 |

362.4 |

911.7 |

0.149 |

9,080 |

18.0 |

2,000 |

816 |

|

240 |

30/3.2 |

7/3.2 |

10,210 |

241.3 |

56.29 |

297.6 |

22.4 |

9.6 |

668.9 |

441.3 |

1,110 |

0.122 |

9,080 |

18.0 |

2,000 |

932 |

|

330 |

26/4.0 |

7/3.1 |

10,950 |

326.8 |

52.84 |

379.6 |

25.3 |

9.3 |

905.4 |

414.2 |

1,320 |

0.0904 |

8,360 |

19.0 |

2,000 |

1,128 |

|

410 |

26/4.5 |

7/3.5 |

13,910 |

413.4 |

67.35 |

480.8 |

28.5 |

10.5 |

1,145 |

527.9 |

1,673 |

0.0714 |

8,360 |

19.0 |

2,000 |

1,322 |

|

480 |

45/3.7 |

7/2.47 |

11,260 |

483.8 |

33.54 |

517.34 |

29.6 |

7.41 |

1336.1 |

262.9 |

1,599 |

0.0610 |

7,250 |

20.8 |

2,000 |

1,425 |

|

520 |

54/3.5 |

7/3.5 |

15,600 |

519.5 |

67.35 |

586.9 |

31.5 |

10.5 |

1,441 |

527.9 |

1,969 |

0.0569 |

7,990 |

19.5 |

1,600 |

1,504 |

|

610 |

54/3.8 |

7/3.8 |

18,350 |

612.4 |

79.38 |

691.8 |

34.2 |

11.4 |

1,698 |

622.2 |

2,320 |

0.0481 |

7,990 |

19.5 |

1,600 |

1,682 |

|

680 |

54/4.0 |

7/4.0 |

19,810 |

678.8 |

87.99 |

766.8 |

36.0 |

12.0 |

1,882 |

689.8 |

2,572 |

0.0436 |

7,990 |

19.5 |

1,600 |

1,797 |

|

680 |

45/4.4 |

7/2.9 |

15,580 |

684.5 |

46.24 |

730.7 |

35.1 |

8.7 |

1,898 |

362.4 |

2,260 |

0.0431 |

7,250 |

20.8 |

1,600 |

1,787 |

|

810 |

45/4.8 |

7/3.2 |

18,480 |

814.5 |

56.29 |

870.8 |

38.4 |

9.6 |

2,259 |

441.3 |

2,700 |

0.0363 |

7,250 |

20.8 |

1,600 |

2,004 |

|

1,160 |

84/4.2 |

7/4.2 |

27,830 |

1.163 |

96.95 |

1,260 |

46.2 |

12.6 |

3,236 |

759.8 |

3,996 |

0.0254 |

7,430 |

20.5 |

1,200 |

2,573 |

|

1,520 |

84/4.8 |

7/4.8 |

36,390 |

1.520 |

126.7 |

1,647 |

52.8 |

14.4 |

4,228 |

993.3 |

5,222 |

0.0195 |

7,430 |

20.5 |

1,200 |

3,035 |

Data Sheet TACSR/AW (20.3% Conductivity AW)

|

Conductor Size

(mm2) |

Stranding (Nos./mm) |

Min. Breaking Load (kgf) |

Reference |

||||||||||

|

Cross-sectional Area (mm2) |

Overall Diameter (mm) |

Weight

(kg/km) |

DC Resistance at 20℃ (Oh/km) |

Modulus of Elasticity (kgf/mm2) |

Coefficient of Linear Expansion (10-6/℃) |

Standard Length

(m) |

Current Carrying Capacity (A) |

||||||

|

TAl |

AW |

TAl |

AW |

TAl |

AW |

||||||||

|

120 |

30/2.3 |

7/2.3 |

5,540 |

124.7 |

29.08 |

16.1 |

6.9 |

536.5 |

0.219 |

8,100 |

19.2 |

2,000 |

624 |

|

160 |

30/2.6 |

7/2.6 |

6,980 |

159.3 |

37.16 |

18.2 |

7.8 |

685.4 |

0.171 |

8,100 |

19.2 |

2,000 |

734 |

|

200 |

30/2.9 |

7/2.9 |

8,640 |

198.2 |

46.24 |

20.3 |

8.7 |

852.8 |

0.138 |

8,100 |

19.2 |

2,000 |

847 |

|

210 |

30/3.2 |

7/3.2 |

10,160 |

241.3 |

56.29 |

22.4 |

9.6 |

1,038 |

0.113 |

8,100 |

19.2 |

2,000 |

968 |

|

330 |

26/4.0 |

7/3.1 |

11,200 |

326.8 |

52.84 |

25.3 |

9.3 |

1,252 |

0.0856 |

7,620 |

20.0 |

2,000 |

1,159 |

|

410 |

26/4.5 |

7/3.5 |

14,230 |

413.4 |

67.35 |

28.5 |

10.5 |

1,587 |

0.0676 |

7,630 |

20.0 |

2,000 |

1,358 |

|

480 |

45/3.7 |

7/2.47 |

11,260 |

483.84 |

33.54 |

29.6 |

7.4 |

1,561 |

0.0595 |

6,910 |

21.5 |

2,000 |

1,437 |

|

520 |

54/3.5 |

7/3.5 |

15,920 |

519.5 |

67.35 |

31.5 |

10.5 |

1,883 |

0.0544 |

7,390 |

20.4 |

1,600 |

1,537 |

|

610 |

54/3.8 |

7/3.8 |

18,730 |

612.4 |

79.38 |

34.2 |

11.4 |

2,219 |

0.0461 |

7,330 |

20.4 |

1,600 |

1,717 |

|

680 |

45/4.4 |

7/2.9 |

15,580 |

684.5 |

46.24 |

35.1 |

8.7 |

2,201 |

0.0422 |

6,900 |

21.5 |

1,600 |

1,805 |

|

810 |

45/4.8 |

7/3.2 |

18,730 |

814.5 |

56.29 |

38.4 |

9.6 |

2,628 |

0.0354 |

6,910 |

21.5 |

1,600 |

2,028 |

|

950 |

84/3.8 |

7/3.8 |

23,780 |

952.6 |

79.38 |

41.8 |

11.4 |

3,170 |

0.0302 |

7,030 |

21.2 |

1,200 |

2,292 |

|

1,160 |

84/4.2 |

7/4.2 |

28,720 |

1,163 |

96.95 |

46.2 |

12.6 |

3,872 |

0.0247 |

7,030 |

21.2 |

1,200 |

2,606 |

|

1,520 |

84/4.8 |

7/4.8 |

37,520 |

1,520 |

126.7 |

52.8 |

14.4 |

5,060 |

0.0189 |

7,030 |

21.2 |

1,200 |

3,075 |

Date Sheet TACSR/AW (23% Conductivity AW)

|

Conductor Size

(mm2) |

Stranding (Nos./mm) |

Min. Breaking Load (kgf) |

Reference |

||||||||||

|

Cross-sectional Area (mm2) |

Overall Diameter (mm) |

Weight

(kg/km) |

DC Resistance at 20℃ (Oh/km) |

Modulus of Elasticity (kgf/mm2) |

Coefficient of Linear Expansion (10-6/℃) |

Standard Length

(m) |

Current Carrying Capacity (A) |

||||||

|

TAl |

AW |

TAl |

AW |

TAl |

AW |

||||||||

|

120 |

30/2.3 |

7/2.3 |

7/2.3 |

124.7 |

29.08 |

16.1 |

6.9 |

528.9 |

0.217 |

7,980 |

19.4 |

2,000 |

625 |

|

160 |

30/2.6 |

7/2.6 |

7/2.6 |

159.3 |

37.16 |

18.2 |

7.8 |

675.7 |

0.170 |

7,980 |

19.4 |

2,000 |

736 |

|

200 |

30/2.9 |

7/2.9 |

7/2.9 |

198.2 |

46.24 |

20.3 |

8.7 |

840.7 |

0.136 |

7,980 |

19.4 |

2,000 |

854 |

|

210 |

30/3.2 |

7/3.2 |

7/3.2 |

241.3 |

56.29 |

22.4 |

9.6 |

1,024 |

0.112 |

7,980 |

19.4 |

2,000 |

973 |

|

330 |

26/4.0 |

7/3.1 |

7/3.1 |

326.8 |

52.84 |

25.3 |

9.3 |

1,238 |

0.085 |

7,540 |

20.2 |

2,000 |

1,163 |

|

410 |

26/4.5 |

7/3.5 |

7/3.5 |

413.4 |

67.35 |

28.5 |

10.5 |

1,570 |

0.0671 |

7,550 |

20.2 |

2,000 |

1,363 |

|

480 |

45/3.7 |

7/2.47 |

7/2.47 |

483.84 |

33.54 |

29.6 |

7.4 |

1,550 |

0.0592 |

6,880 |

20.6 |

2,000 |

1,441 |

|

520 |

54/3.5 |

7/3.5 |

7/3.5 |

519.5 |

67.35 |

31.5 |

10.5 |

1,865 |

0.0541 |

7,330 |

20.6 |

1,600 |

1,541 |

|

610 |

54/3.8 |

7/3.8 |

7/3.8 |

612.4 |

79.38 |

34.2 |

11.4 |

2,198 |

0.0458 |

7,320 |

20.6 |

1,600 |

1,722 |

|

680 |

45/4.4 |

7/2.9 |

7/2.9 |

684.5 |

46.24 |

35.1 |

8.7 |

2,189 |

0.0420 |

6,860 |

21.6 |

1,600 |

1,809 |

|

810 |

45/4.8 |

7/3.2 |

7/3.2 |

814.5 |

56.29 |

38.4 |

9.6 |

2,613 |

0.0353 |

6,880 |

21.6 |

1,600 |

2,031 |

|

950 |

84/3.8 |

7/3.8 |

7/3.8 |

952.6 |

79.38 |

41.8 |

11.4 |

3,149 |

0.0300 |

6,980 |

21.3 |

1,200 |

2,299 |

|

1,160 |

84/4.2 |

7/4.2 |

7/4.2 |

1,163 |

96.95 |

46.2 |

12.6 |

3,847 |

0.0246 |

6,980 |

21.3 |

1,200 |

2,611 |

|

1,520 |

84/4.8 |

7/4.8 |

7/4.8 |

1,520 |

126.7 |

52.8 |

14.4 |

5,027 |

0.0189 |

6,980 |

21.3 |

1,200 |

3,075 |

Data Sheet TACSR Conductor

|

PROPERTIES |

TACSR (ACSR MOOSE EQUIVALENT |

TACSR (ACSR ZEBRA EQUIVALENT) |

TACSR (ACSR PANTHER EQUIVALENT) |

|||

|

Typical factors |

3.53 mm |

0.1378 in |

3.18 mm |

0.1252 in |

3.00 mm |

0.1181 in |

|

Reference specifications |

IEC 62004 |

IEC 62004 |

IEC 62004 |

|||

|

Total cross section area |

596.99 mm2 |

0.9253 print2 |

484.25 mm2 |

0.7506 print2 |

261.50 mm2 |

0.4054 print2 |

|

Conductive wire |

Al Zr ATI |

Al Zr ATI |

Al Zr ATI |

|||

|

Core wire |

Galvanized Steel |

Galvanized Steel |

Galvanized Steel |

|||

|

Conductor diameter |

31.77 mm |

1.2508 in |

28.62 mm |

1.1268 in |

21.00 mm |

0.8268 in |

|

Weight |

2004 |

1346.6 |

1621 |

1089.3 |

972 |

653.2 |

|

kg/gm |

Ibs/mile |

kg/km |

Ibs/mile |

kg/km |

Ibs/mile |

|

|

Ultimate tensile strength |

16438 kg |

36239.54 lbs |

14407 kg |

31761.96 lbs |

10119 kg |

22308.55 lbs |

|

DC resistance at |

0.06 |

0.09 |

0.07 |

0.11 |

0.14 |

0.22 |

|

20°C temperature |

0/km |

Q/mile |

About/km |

Q/mile |

n/km |

Q/mile |

|

Maximum operating temperature |

150°C |

302°F |

150°C |

302°F |

150°C |

302°F |

|

Current carrying capacity at maximum operating temperature |

1509 Amp |

1302 Amp |

831 Amp |

|||

Why Choose TACSR & TACSR/AW Conductors?

✅ High-Temperature Performance:

The thermally resistant aluminum conductor steel reinforced design allows operation at high temperatures without reducing tensile strength.

✅ Enhanced Sag-Tension Control:

Low-sag aluminum conductor properties reduce line sag, improving power transmission efficiency.

✅ Energy-Efficient and Durable:

TACSR conductor for power transmission lines ensures stable performance in extreme environments.

✅ Superior Corrosion Resistance:

TACSR/AW aluminum conductor with aluminum-clad steel core enhances durability in coastal and industrial environments.

✅ Longer Service Life & Cost-Effective:

High-strength aluminum conductor design improves longevity, reducing maintenance costs.