Application

Stranded Class 2 bare copper wire to BS EN 60228 / IEC 60228 cables are non insulated and non sheathed soft drawn copper to BS6360/81. Stranded bare soft or annealed copper conductors are recommended for use as neutrals, in circuit ground connections as well as machinery and equipment grounding systems. Soft copper may be used for transformer drop leads or other non-tension hook-up jumpers.

Standard

Basic design to BS 6360 and BS EN 60228 / IEC 60228

Features And Benefits

Stranded bare soft or annealed copper conductors are suitable for direct burial and do not suffer from the inherent corrosion problems that an aluminum conductor would. Copper is almost twice as conductive as aluminum. Copper is easier than aluminum to terminate and join at splices and joints.

Construction

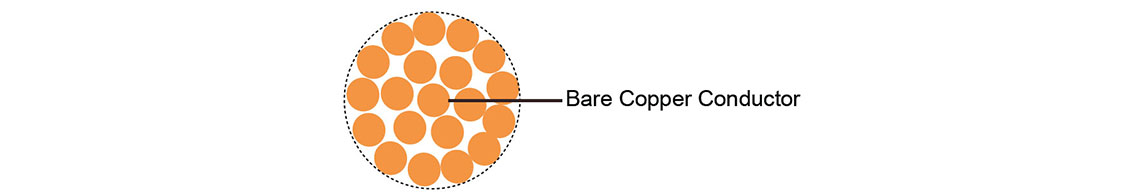

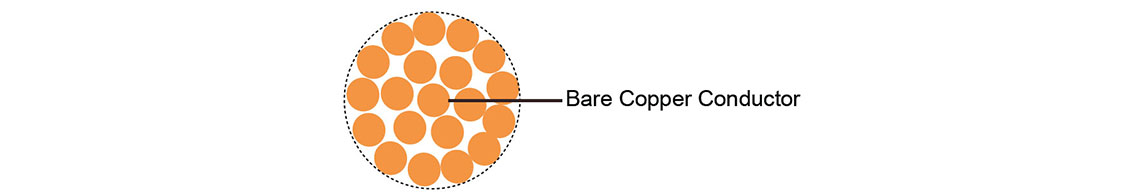

Bare copper conductors are compressed concentric-lay-stranded consisting of one or more layers of wire wrapped helically around a straight round central wire. Each successive layer has six wires more than the layer immediately beneath. Greater flexibility is afforded by using Class 2 stranding. The direction of lay for the outer layer is left hand lay. In 7,19 and 37 wire constructions, the direction of lay of each successive layer is reversed.

Technical Infomation

| Construction characteristics |

| Conductor material |

Electrolytic, stranded and bare copper |

| Conductor class |

Class 2 according to BS EN60228 |

| Usage characteristics |

| Minimum Installation Temperature |

0°C |

| Maximum Installation Temperature |

60°C |

| Minimum Operating Temperature |

-15°C |

| Maximum Operating Temperature |

70°C |

| Maximum conductor temperature |

90°C |

| Linear resistance @20°C |

According to BS EN60228 / IEC 60228 |

| Short-circuit max. conductor temperature |

370°C |

| Mechanical characteristics |

| Min. Bending Radius |

35mm^2 up to 400mm^2 = 6 x OD |

Construction Parameters

| Cross Section |

No./Nominal Diameter of Strands |

Conductor Nominal Diameter |

Approx. Weight |

Max. DC Resistance at 20°C |

| mm² |

No./mm |

mm |

kg/km |

Ω/km |

| 50 mm² |

19/1.78 |

8.90 |

430 |

0.387 |

| 70 mm² |

19/2.14 |

10.70 |

625 |

0.268 |

| 95 mm² |

19/2.52 |

12.60 |

866 |

0.193 |

| 120 mm² |

37/2.03 |

14.25 |

1090 |

0.153 |

| 185 mm² |

37/2.52 |

17.64 |

1680 |

0.099 |

| 240 mm² |

61/2.25 |

20.30 |

2220 |

0.075 |

| 300 mm² |

61/2.52 |

22.68 |

2780 |

0.060 |