GTACSR/GZTACSR Conductors Application

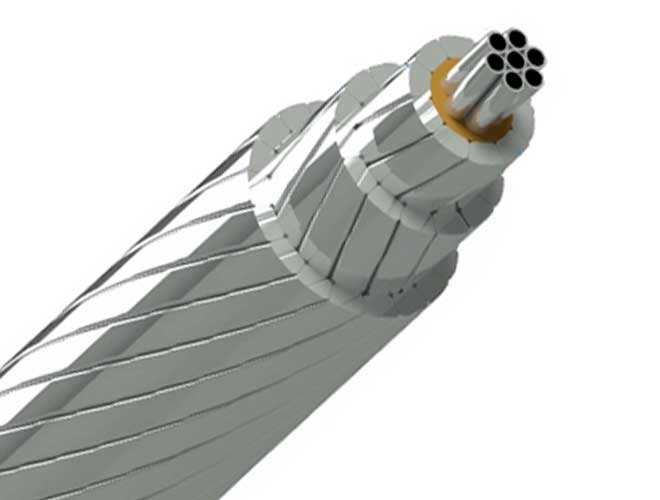

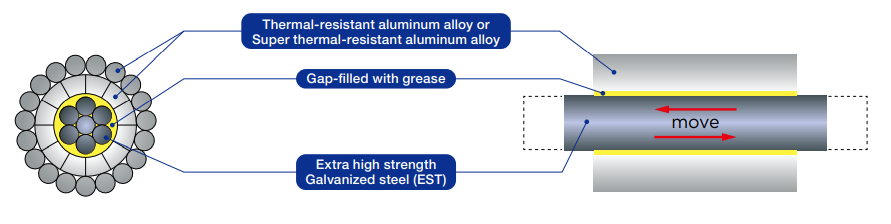

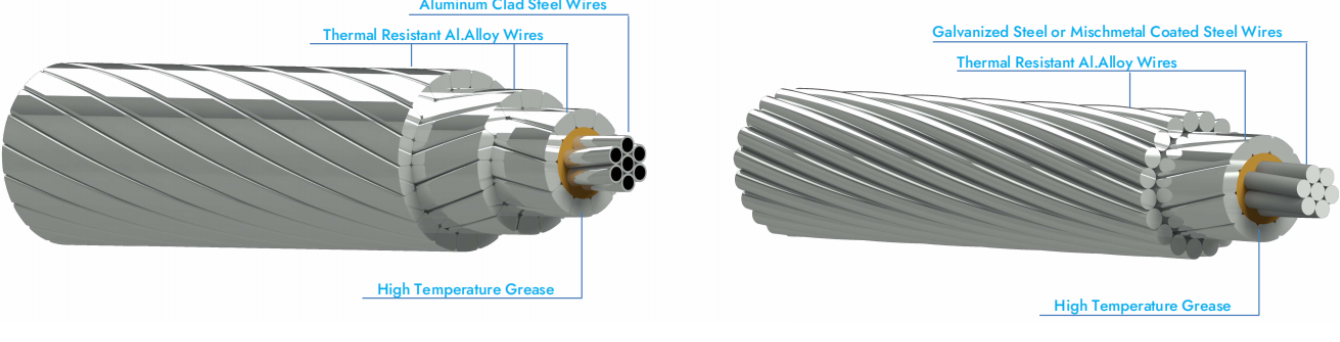

GTACSR/GZTACSR has a unique construction featuring a small gap between the steel core and (Super)Thermal-resistant aluminum alloy layer. The combination of the (Super) Thermal resistant aluminum alloy and the "Gap construction" offers excellent sag and current-carrying characteristics. GTACSR/GZTACSR is useful to up-rate an existing transmission line by simply replacing the existing conductor to GTACSR/GZTACSR.

GTACSR & GZTACSR Conductors Construction

Aluminium-Zirconium wires (Type-AT3 or AT-1), concentrically stranded over a steel core maintaing gap between the Steel core and first Aluminium Layer.

Values based on following Specifications:

• Thermal-resistant aluminium alloy wires (Type-AT3 or AT1) for overhead line conductor as per IEC 62004

• Concentric lay stranded overhead electrical conductors IEC 61089, IEC 62420

• Zinc-coated steel wires for stranded conductors IEC 888, ASTM B957 & more

• Zinc–5% Aluminum-Mischmetal Alloy-Coated Steel Core Wire EN 50540, ASTM B802, ASTM B803 or ASTM B958.

• Aluminium Clad Steel Wires, IEC 61232, ASTM B415, EN 50540 & More

GTACSR & GZTACSR Conductors Features:

• These can operate upto 210°C with specified strength loss,

• Can carry 100~150% more current as that of ACSR of the same size.

• For uprating lines, no modifications or reinforcement is required to the existing towers

• Limiting the sag increase with the increase of the temperature by the thermal expansion coefficient above knee-point related to the steel core

GTACSR & GZTACSR Standard: IEC 62420, IEC 62219, IEC 60888, IEC 62004

GTACSR & GZTACSR Parameter

| Conductor Size | Stranding | Cross-Sectional Area | Diameter of Complete Conductor | Weight | Rated Strength | DCResistance @20°C | Current Capacity | ||||||||||

| No. of Wires | Wire diameter | TAL | Steel | Total | TAL | Steel | Total with Grease | Extra High Strength | Ultra High Strength | ||||||||

| TAL | Steel | TAL | Steel | @ 85°C | @ 150°C | @ 210°C | |||||||||||

| (mm²) | (No.) | (No.) | (mm) | (mm) | (mm²) | (mm²) | (mm²) | (mm) | (Kg/Km) | (Kg/Km) | (Kg/Km) | (KN) | (KN) | (Ω/Km) | (Ampere) | (Ampere) | (Ampere) |

| 175 | 8/12 | 7 | 3.35 (TW) | 2.10 | 176.20 | 24.25 | 200.45 | 17.50 | 486.98 | 189.44 | 691.42 | 66.14 | 66.87 | 0.1668 | 409 | 698 | 859 |

| 190 | 12/16 | 7 | 2.92 (TW) | 2.30 | 187.30 | 29.08 | 216.38 | 18.20 | 517.66 | 227.24 | 761.90 | 74.44 | 75.46 | 0.1569 | 425 | 728 | 896 |

| 195 | 20/12 | 7 | 2.40(R) 2.88(TW) | 2.20 | 168.80 | 26.61 | 195.41 | 18.06 | 466.53 | 207.91 | 690.44 | 69.51 | 70.31 | 0.1741 | 403 | 689 | 849 |

| 218 | 18/12 | 7 | 2.78(R) 2.94(TW) | 2.25 | 190.50 | 27.83 | 218.33 | 19.10 | 526.51 | 217.47 | 759.98 | 74.47 | 75.31 | 0.1542 | 433 | 744 | 917 |

| 240 | 8/12 | 7 | 4.02 (TW) | 2.40 | 253.40 | 31.67 | 285.07 | 20.60 | 700.35 | 247.43 | 964.78 | 88.34 | 89.45 | 0.1159 | 507 | 877 | 1083 |

| 248 | 12/8 | 7 | 3.71(TW) | 2.40 | 216.12 | 31.67 | 247.79 | 19.40 | 597.32 | 247.43 | 862.75 | 83.00 | 84.11 | 0.1360 | 463 | 796 | 981 |

| 287 | 18/12 | 7 | 3.15(R) 3.43(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 279.33 | 993.04 | 94.85 | 96.10 | 0.1171 | 510 | 886 | 1096 |

| 287 | 20/12 | 7 | 2.90(R) 3.55(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 279.33 | 993.04 | 95.33 | 96.58 | 0.1171 | 510 | 886 | 1096 |

| 310 | 16/12 | 7 | 3.90(R) 3.69(TW) | 2.80 | 319.40 | 43.10 | 362.50 | 24.40 | 882.76 | 336.78 | 1241.54 | 116.10 | 117.60 | 0.0920 | 589 | 1033 | 1281 |

| 400 | 18/12 | 7 | 3.90(R) 4.45(TW) | 2.80 | 401.40 | 43.10 | 444.50 | 26.90 | 1109.40 | 336.78 | 1468.18 | 129.16 | 130.67 | 0.0732 | 673 | 1190 | 1480 |

| 410 | 14/12 | 7 | 4.90(R) 3.99(TW) | 3.00 | 414.00 | 49.48 | 463.48 | 27.60 | 1144.22 | 386.61 | 1554.83 | 138.95 | 140.68 | 0.0710 | 687 | 1218 | 1515 |

| 439 | 15/12 | 7 | 4.50(R) 4.04(TW) | 2.90 | 392.50 | 46.24 | 438.74 | 26.84 | 1084.80 | 361.27 | 1469.07 | 132.44 | 134.06 | 0.0749 | 665 | 1176 | 1462 |

| 462 | 14/12 | 7 | 4.90(R) 3.99(TW) | 2.95 | 414.30 | 47.84 | 462.14 | 27.60 | 1145.05 | 373.83 | 1542.88 | 136.47 | 138.14 | 0.0709 | 687 | 1219 | 1516 |

| 540 | 24/14/10 | 7 | 3.55(R) 3.98(TW) | 3.10 | 536.20 | 52.83 | 589.03 | 31.30 | 1483.12 | 412.81 | 1920.93 | 164.15 | 166.00 | 0.0548 | 799 | 1436 | 1793 |

| 620 | 16/12/12 | 7 | 4.80(TW) 4.75(TW) 3.47(TW) | 3.20 | 615.70 | 56.30 | 672.00 | 31.50 | 1703.01 | 439.88 | 2168.89 | 177.96 | 179.93 | 0.0478 | 856 | 1539 | 1922 |

GTACSR/AW & GZTACSR/AW

| Conductor Size | Cross-Sectional Area | Stranding | Diameter of Complete Conductor | Weight | Rated Strength | DC Resistance @20°C | Current Capacity | ||||||||||

| STAL | Steel | Total | No. of STAL Wires | No. of STAL Layers | No. of Steel Wires | Dia. of Steel Wires | STAL | Steel | Total | High Strength | Extra High Strength | ||||||

| @ 85°C | @ 150°C | @ 210°C | |||||||||||||||

| (mm²) | (mm²) | (mm²) | (mm²) | (No.) | (No.) | (No.) | (mm) | (mm) | (Kg/Km) | (Kg/Km) | (Kg/Km) | (KN) | (KN) | (Ω/Km) | (Ampere) | (Ampere) | (Ampere) |

| 175 | 8/12 | 7 | 3.35 (TW) | 2.10 | 176.20 | 24.25 | 200.45 | 17.50 | 486.98 | 160.46 | 647.44 | 57.65 | 62.26 | 0.1593 | 418 | 714 | 879 |

| 190 | 12/16 | 7 | 2.92 (TW) | 2.30 | 187.30 | 29.08 | 216.38 | 18.20 | 517.66 | 192.48 | 710.14 | 65.28 | 69.93 | 0.1490 | 436 | 747 | 919 |

| 195 | 20/12 | 7 | 2.40(R) 2.88(TW) | 2.20 | 168.80 | 26.61 | 195.41 | 18.06 | 466.53 | 176.11 | 642.64 | 60.20 | 65.25 | 0.1652 | 414 | 708 | 871 |

| 218 | 18/12 | 7 | 2.78(R) 2.94(TW) | 2.25 | 190.50 | 27.83 | 218.33 | 19.10 | 526.51 | 184.21 | 710.72 | 64.73 | 70.02 | 0.1470 | 444 | 762 | 940 |

| 240 | 8/12 | 7 | 4.02 (TW) | 2.40 | 253.40 | 31.67 | 285.07 | 20.60 | 700.35 | 209.59 | 909.94 | 78.36 | 83.43 | 0.1112 | 518 | 895 | 1105 |

| 248 | 12/8 | 7 | 3.71(TW) | 2.40 | 216.12 | 31.67 | 247.79 | 19.40 | 597.32 | 209.59 | 806.91 | 73.03 | 78.09 | 0.1295 | 474 | 816 | 1006 |

| 287 | 18/12 | 7 | 3.15(R) 3.43(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 236.60 | 930.32 | 83.59 | 89.31 | 0.1117 | 523 | 908 | 1122 |

| 287 | 20/12 | 7 | 2.90(R) 3.55(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 26.60 | 720.32 | 84.07 | 89.79 | 0.1117 | 523 | 908 | 1122 |

| 310 | 16/12 | 7 | 3.90(R) 3.69(TW) | 2.80 | 319.40 | 43.10 | 362.50 | 24.40 | 882.76 | 285.27 | 1168.03 | 102.52 | 109.41 | 0.0880 | 602 | 1056 | 1310 |

| 400 | 18/12 | 7 | 3.90(R) 4.45(TW) | 2.80 | 401.40 | 43.10 | 444.50 | 26.90 | 1109.40 | 285.27 | 1394.67 | 115.59 | 122.48 | 0.0706 | 685 | 1212 | 1507 |

| 410 | 14/12 | 7 | 4.90(R) 3.99(TW) | 3.00 | 414.00 | 49.48 | 463.48 | 27.60 | 1144.22 | 327.48 | 1471.70 | 123.36 | 131.28 | 0.0682 | 700 | 1242 | 1545 |

| 439 | 15/12 | 7 | 4.50(R) 4.04(TW) | 2.90 | 392.50 | 46.24 | 438.74 | 26.84 | 1084.80 | 306.00 | 1390.80 | 117.87 | 125.27 | 0.0720 | 678 | 1200 | 1491 |

| 462 | 14/12 | 7 | 4.90(R) 3.99(TW) | 2.95 | 414.30 | 47.84 | 462.14 | 27.60 | 1145.05 | 316.65 | 1461.70 | 121.40 | 129.05 | 0.0682 | 700 | 1242 | 1545 |

| 540 | 24/14/10 | 7 | 3.55(R) 3.98(TW) | 3.10 | 536.20 | 52.83 | 589.03 | 31.30 | 1483.12 | 349.67 | 1832.79 | 149.36 | 156.23 | 0.0536 | 808 | 1452 | 1812 |

| 620 | 16/12/12 | 7 | 4.80(TW) 4.75(TW) 3.47(TW) | 3.20 | 615.70 | 56.30 | 672.00 | 31.50 | 1703.01 | 372.60 | 2075.61 | 162.19 | 169.51 | ||||