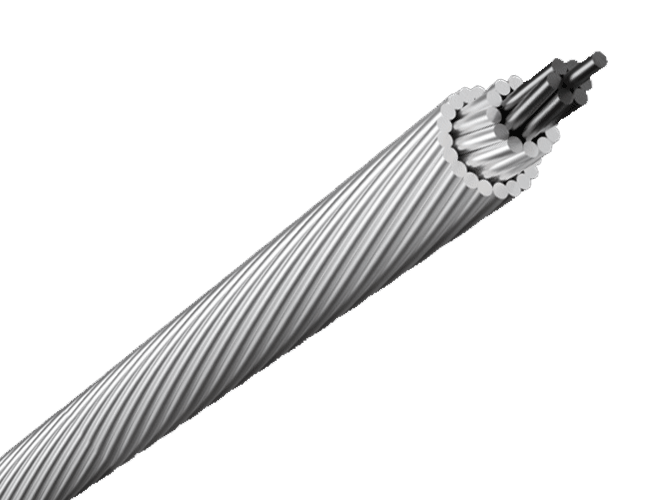

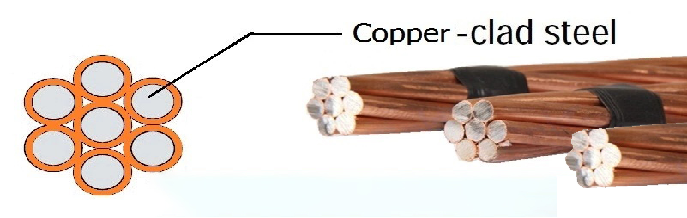

CCS-Copper Clad Steel Strand

Copper clad steel wire (CCS) combines the high tensile strength of steel as its core and the conductivity properties of copper as its outer layer. The core material is usually low carbon steel and is typically used as either grounding wire or the inner conductor of coaxial cables.

Applications

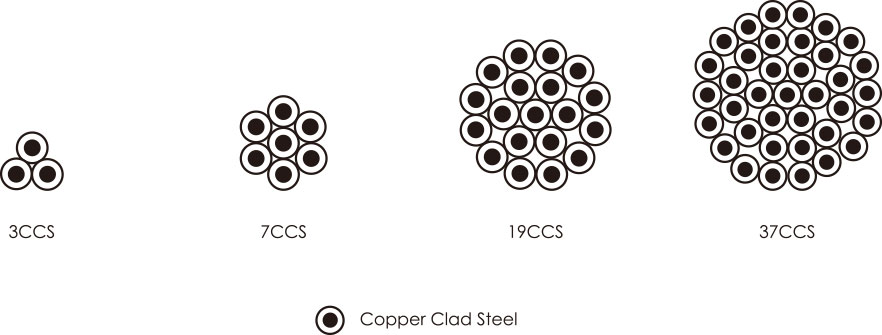

DSA Copper Clad Steel stranded conductors are used in place of copper conductors in grounding applications and systems.conductors are classified as follows: Grade 40 HS, Grade 30 HS, Grade 30 EHS, Grade 40 DSA, and Grade 30 DSA.

CCS strand wire is divided into soft state and hard state with perfect conductivity, which is a good choice for various industries such as communications, electrical power and electronics.

Characteristics

1.High conductivity (up to 70% and above)

The copper-clad strand wire produced by our company generally has a conductivity of 30%-70%, and more than 70% can be customized according to customer requirements.

2.High tensile strength

The multi-stranded copper-clad strand wire has high tensile strength and can be made into copper-clad steel strand wire with high electrical conductivity and high tensile strength after being enhanced by special treatment process to be suitable for special use occasions.

3.Long life

The copper plating of single-stranded copper-clad round steel (copperweld steel) of multi-stranded copper-clad strand is thick, the excellent production process makes copper layer tightly combined and bent 180-360 degrees without cracking and its life is long and can be more than 30 years.

4.Low cost

The characteristics of high conductivity and corrosion resistance have greatly reduced the number of grounding conductors used in grounding projects, which can significantly save costs and achieve outstanding economic benefits.

5.Convenient construction and transportation

The single length of the copper-clad copperweld strand can be up to 100 meters, because the 100-meter package or the hundred-meter cable can be transported more easily. The welding between the grounding grids during the construction is recommended to use the exothermic welding series products produced by our company. There are different shapes of molds for exothermic welding, so that different permanent joints can be randomly welded. The construction operation is simple and easy to learn, and the various conductors of the grounding grid are welded together to become a true maintenance-free device.

Specifications

ASTM B-227 Hard drawn copper-clad steel wire

ASTM B-910 Annealed copper-clad steel wire

ASTM B-228 Concentric-lay-stranded copper-clad steel conductors

Technical Parameters of ASTM B 228-CCS (Conductivity 20.3)

| Size Designation | Conductor Area |

No.of Wires | Diameter mm |

Min.Rated Breaking Strength kN |

Weight kg/km |

Max.D.C. Resistance at 20℃ Ω/km |

|||

| AWG | mm² | in² | Wire | Cond. | Grade 40 HS |

Grade 40 DSA |

Grade 40 | ||

| 19 No.5 | 318.71 | 0.4940 | 19 | 4.620 | 23.11 | 216.66 | 76.68 | 2660.8 | 0.14423 |

| 19 No.6 | 252.71 | 0.3917 | 19 | 4.115 | 20.57 | 179.45 | 60.81 | 2110.2 | 0.18183 |

| 19 No.7 | 200.45 | 0.3107 | 19 | 3.665 | 18.31 | 148.29 | 48.23 | 1674.2 | 0.22937 |

| 19 No. 8 | 158.97 | 0.2464 | 19 | 3.264 | 16.31 | 122.46 | 38.27 | 1327.4 | 0.28896 |

| 19 No. 9 | 126.06 | 0.1954 | 19 | 2.906 | 14.53 | 100.86 | 30.33 | 1052.6 | 0.36452 |

| 7 No. 4 | 148.06 | 0.2295 | 7 | 5.189 | 15.57 | 96.15 | 35.61 | 1231.5 | 0.30930 |

| 7 No. 5 | 117.42 | 0.1820 | 7 | 4.620 | 13.87 | 79.84 | 28.25 | 976.5 | 0.38978 |

| 7 No. 6 | 93.10 | 0.1443 | 7 | 4.115 | 12.34 | 66.10 | 22.41 | 774.3 | 0.4915 |

| 7 No.7 | 73.87 | 0.1145 | 7 | 3.665 | 11.00 | 54.63 | 17.76 | 614.5 | 0.6201 |

| 7 No. 8 | 58.56 | 0.09077 | 7 | 3.264 | 9.78 | 45.12 | 14.10 | 487.1 | 0.7812 |

| 7 No. 9 | 46.44 | 0.07198 | 7 | 2.906 | 8.71 | 37.16 | 11.18 | 386.2 | 0.9859 |

| 7 No. 10 | 36.83 | 0.05708 | 7 | 2.588 | 7.77 | 30.73 | 8.87 | 306.3 | 1.2422 |

| 3 No. 5 | 50.32 | 0.07800 | 3 | 4.620 | 9.96 | 36.10 | 12.78 | 417.7 | 0.9082 |

| 3 No. 6 | 39.90 | 0.06185 | 3 | 4.115 | 8.86 | 29.91 | 10.14 | 331.3 | 1.1447 |

| 3 No. 7 | 31.65 | 0.04905 | 3 | 3.665 | 7.90 | 24.71 | 8.04 | 262.7 | 1.4440 |

| 3 N0. 8 | 25.10 | 0.03890 | 3 | 3.264 | 7.04 | 20.41 | 6.38 | 208.3 | 1.8193 |

| 3 No. 9 | 19.90 | 0.03085 | 3 | 2.906 | 6.27 | 16.81 | 5.05 | 165.2 | 2.2957 |

| 3 No. 10 | 15.78 | 0.02446 | 3 | 2.588 | 5.59 | 13.90 | 4.01 | 131.0 | 2.8929 |

| 3 No. 12 | 9.93 | 0.01539 | 3 | 2.052 | 4.42 | 7.32 | 2.55 | 82.4 | 4.5573 |

ASTM B 228-CCS (Conductivity 20.3)

| Size Designation | Conductor Area |

No.of wires | Diameter mm |

Min.Rated Breaking Strength kN | Weight kg/km |

Max. Resistance at 20℃ Ω/km |

||||

| AWG | mm² | in² | Wire | Cond. | Grade 30HS | Grade 30 EHS | Grade 30 DSA | Grade 30 | ||

| 19 No.5 | 318.71 | 0.4940 | 19 | 4.620 | 23.11 | 239.64 | 288.54 | 86.28 | 2634.0 | 0.19227 |

| 19 No.6 | 252.71 | 0.3917 | 19 | 4.115 | 20.57 | 197.68 | 239.51 | 68.41 | 2087.9 | 0.24240 |

| 19 No.7 | 200.45 | 0.3107 | 19 | 3.665 | 18.31 | 162.74 | 197.72 | 54.23 | 1656.3 | 0.30576 |

| 19 No. 8 | 158.97 | 0.2464 | 19 | 3.264 | 16.31 | 133.98 | 162.65 | 43.06 | 1313.6 | 0.3852 |

| 19 No. 9 | 126.06 | 0.1954 | 19 | 2.906 | 14.53 | 109.93 | 132.02 | 34.12 | 1041.7 | 0.4862 |

| 7 No. 4 | 148.06 | 0.2295 | 7 | 5.189 | 15.57 | 106.86 | 126.87 | 40.07 | 1218.7 | 0.4124 |

| 7 No. 5 | 117.42 | 0.1820 | 7 | 4.620 | 13.87 | 88.28 | 106.28 | 31.78 | 966.4 | 0.5197 |

| 7 No. 6 | 93.10 | 0.1443 | 7 | 4.115 | 12.34 | 72.86 | 88.24 | 25.21 | 766.3 | 0.6552 |

| 7 No.7 | 73.87 | 0.1145 | 7 | 3.665 | 11.00 | 59.97 | 72.86 | 19.99 | 608.1 | 0.8268 |

| 7 No. 8 | 58.56 | 0.09077 | 7 | 3.264 | 9.78 | 49.34 | 59.92 | 15.86 | 482.0 | 1.0414 |

| 7 No. 9 | 46.44 | 0.07198 | 7 | 2.906 | 8.71 | 40.51 | 48.63 | 12.57 | 382.2 | 1.3144 |

| 7 No. 10 | 36.83 | 0.05708 | 7 | 2.588 | 7.77 | 33.48 | 39.69 | 9.97 | 303.1 | 1.6559 |

| 3 No. 5 | 50.32 | 0.07800 | 3 | 4.620 | 9.96 | 39.94 | 48.10 | 14.38 | 413.4 | 1.2104 |

| 3 No. 6 | 39.90 | 0.06185 | 3 | 4.115 | 8.86 | 32.95 | 39.92 | 11.41 | 327.8 | 1.5260 |

| 3 No. 7 | 31.65 | 0.04905 | 3 | 3.665 | 7.90 | 27.12 | 32.95 | 9.04 | 260.0 | 1.9250 |

| 3 N0. 8 | 25.10 | 0.03890 | 3 | 3.264 | 7.04 | 22.33 | 27.11 | 7.17 | 206.1 | 2.4253 |

| 3 No. 9 | 19.90 | 0.03085 | 3 | 2.906 | 6.27 | 18.32 | 22.00 | 5.69 | 163.5 | 3.0605 |

| 3 No. 10 | 15.78 | 0.02446 | 3 | 2.588 | 5.59 | 15.14 | 17.95 | 4.51 | 129.6 | 3.855 |

| 3 No. 12 | 9.93 | 0.01539 | 3 | 2.052 | 4.42 | 7.64 | 11.40 | 2.87 | 81.6 | 6.073 |

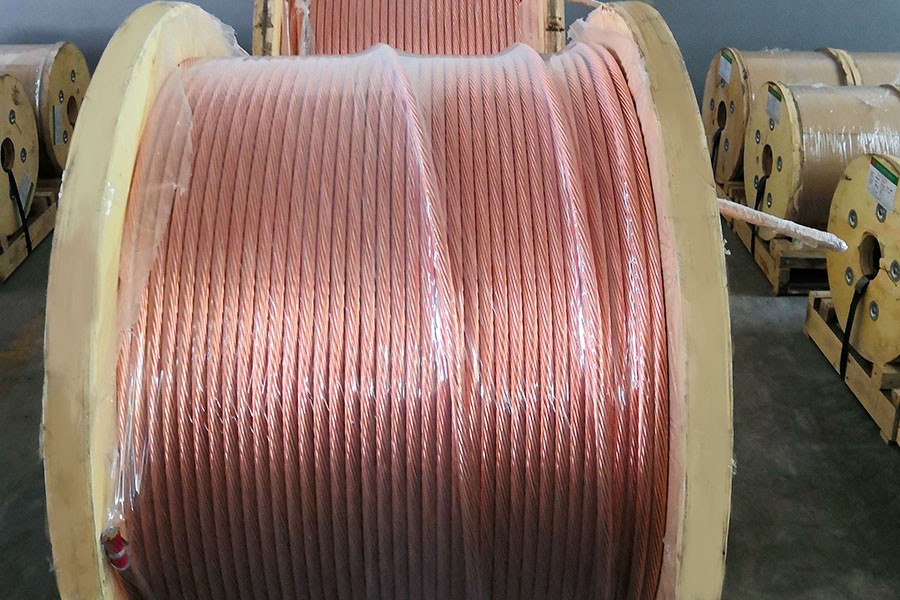

Packing for Copper-Clad Steel Wire Strand