Application

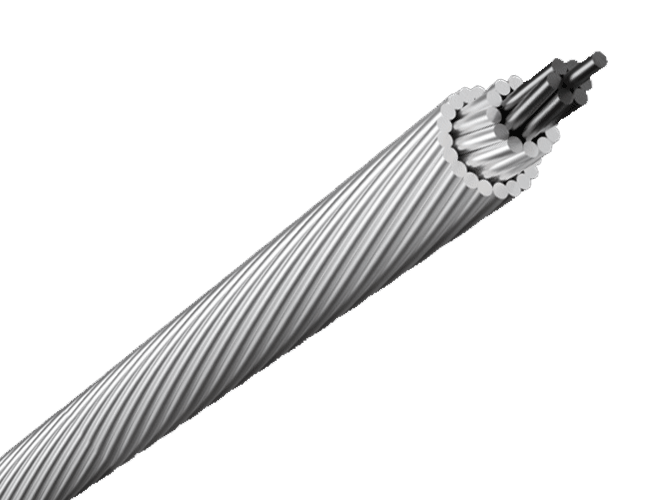

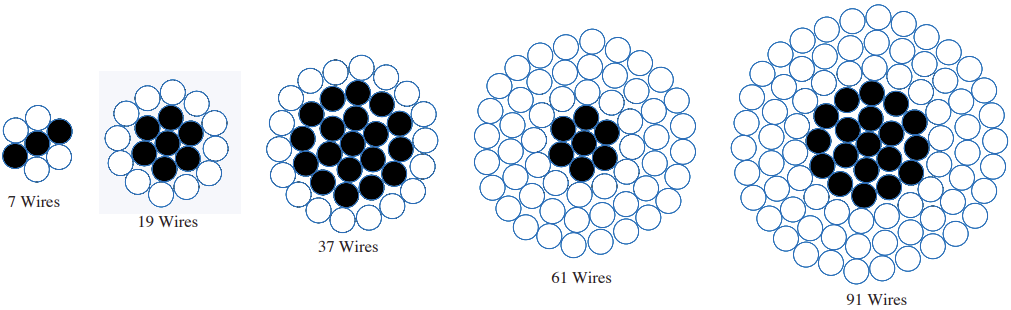

AACSR conductor is suitable for practical overhead transmission applications, especially for conditions like large spans in towers or heavy wire loads from wind and ice which often happens in high altitude areas.AACSR is a concentrically stranded conductor composed of one or more layers of Aluminium -Magnesium -Silicon Alloy wire stranded around a high strength coated steel, core, the core can be to another single-wie or stranded multi-wire. AACSR is available with a steel core of Class A, B, or C galvanizing or Aluminium clad (AW). Additional corrosion protection is available through the application of grease to the core or infusion of the complete cable with grease. The high tensile strength of the 6201-T81 wires combined with the high strength of steel provides an exceptionally high strength conductor with good conductivity, which can be used in long spans. These are used in Transmission and Distribution system to carry the generated electrical energy from the generating station to the end user.

Conductors are supplied on Nonreturnable wooden / steel reels or Returnable steel reels

Features

Offers optimal strength for line design.Improved strength-to-weight ratio

ideal for extra long spans with a heavy load

Excellent corrosion resistance

Construction

Concentric-lay stranded.Galvanized steel core wrapped by a single layer or multiple lavers concentrically stranded Al-Mg-Si 6201 wires

Parameter

IEC 61089 Standard| Code Number | Area | Number of Wires | Wire Dia. | Diameter | Linear Mass | A1/S1 A Conductor | A1/S2 A Conductor | A1/S3 A Conductor | Max.D.C. Resistance at 20℃ | |||||

| Alum. | Steel | Total | AI. | St. | Alum. | Steel | Core | Cond. | Rated Strength | Rated Strength | Rated Strength | |||

| mm² | mm² | mm² | mm² | mm | mm | mm | mm | kg/km | kN | Ω/km | ||||

| 16 | 16 | 2.67 | 18.7 | 6 | 1 | 1.84 | 1.84 | 1.64 | 5.53 | 64.6 | 6.08 | 6.45 | 6.83 | 1.7934 |

| 25 | 25 | 4.17 | 29.2 | 6 | 1 | 2.3 | 2.3 | 2.3 | 6.91 | 100.9 | 9.13 | 9.71 | 10.25 | 1.1478 |

| 40 | 40 | 6.67 | 46.7 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 161.5 | 14.4 | 15.33 | 16.2 | 0.7174 |

| 63 | 63 | 10.5 | 73.5 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11 | 254.4 | 21.63 | 22.37 | 24.15 | 0.4555 |

| 100 | 100 | 16.7 | 117 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.8 | 403.8 | 34.33 | 35.5 | 38.33 | 0.2869 |

| 125 | 125 | 6.94 | 132 | 18 | 1 | 2.97 | 2.97 | 2.97 | 14.9 | 397.9 | 29.17 | 30.14 | 31.04 | 0.2304 |

| 125 | 125 | 20.4 | 145 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.7 | 503.9 | 45.69 | 48.54 | 51.39 | 0.231 |

| 160 | 160 | 8.89 | 169 | 18 | 1 | 3.36 | 3.36 | 3.36 | 16.8 | 509.3 | 36.18 | 37.42 | 38.67 | 0.18 |

| 160 | 160 | 26.1 | 186 | 26 | 7 | 2.8 | 2.18 | 6.53 | 17.7 | 644.9 | 57.69 | 61.34 | 64.99 | 0.1805 |

| 200 | 200 | 11.1 | 211 | 18 | 1 | 3.76 | 3.76 | 3.76 | 18.8 | 636.7 | 44.22 | 45 | 46.89 | 0.144 |

| 200 | 200 | 32.6 | 233 | 26 | 7 | 3.13 | 2.43 | 7.3 | 19.8 | 806.2 | 70.13 | 74.69 | 78.93 | 0.1444 |

| 250 | 250 | 24.6 | 275 | 22 | 7 | 3.8 | 2.11 | 6.34 | 21.6 | 880.6 | 68.72 | 72.16 | 75.6 | 0.1154 |

| 250 | 250 | 40.7 | 291 | 26 | 7 | 3.5 | 2.72 | 8.16 | 22.2 | 1007.7 | 87.67 | 93.37 | 98.66 | 0.1155 |

| 315 | 315 | 21.8 | 337 | 45 | 7 | 2.99 | 1.99 | 5.97 | 23.9 | 1039.3 | 79.03 | 82.08 | 85.13 | 0.0917 |

| 315 | 315 | 51.3 | 366 | 26 | 7 | 3.93 | 3.05 | 9.16 | 24.9 | 1269.7 | 106.83 | 114.02 | 121.2 | 0.0917 |

| 400 | 400 | 27.7 | 428 | 45 | 7 | 3.36 | 2.24 | 6.73 | 26.9 | 1320.1 | 98.36 | 102.23 | 106.1 | 0.0722 |

| 400 | 400 | 51.9 | 452 | 54 | 7 | 3.07 | 3.07 | 9.21 | 27.6 | 1510.3 | 123.04 | 130.3 | 137.56 | 0.0723 |

| 450 | 450 | 31.1 | 481 | 45 | 7 | 3.57 | 2.38 | 7.14 | 28.5 | 1485.2 | 107.47 | 111.82 | 115.87 | 0.0642 |

| 450 | 450 | 58.3 | 508 | 54 | 7 | 3.26 | 3.26 | 9.77 | 29.3 | 1699.1 | 138.42 | 146.58 | 154.75 | 0.0643 |

| 500 | 500 | 34.6 | 535 | 45 | 7 | 3.76 | 2.51 | 7.52 | 30.1 | 1650.2 | 199.41 | 124.25 | 128.74 | 0.0578 |

| 500 | 500 | 64.8 | 565 | 54 | 7 | 3.43 | 3.43 | 10.3 | 30.9 | 1887.9 | 153.8 | 162.87 | 171.94 | 0.0578 |

| 560 | 560 | 38.7 | 599 | 45 | 7 | 3.98 | 2.65 | 7.96 | 31.8 | 1848.2 | 133.74 | 139.16 | 144.19 | 0.0516 |

| 560 | 560 | 70.9 | 631 | 54 | 19 | 3.63 | 2.18 | 10.9 | 32.7 | 2103.4 | 172.59 | 182.52 | 192.45 | 0.0516 |

| 630 | 630 | 43.6 | 674 | 45 | 7 | 4.22 | 2.81 | 8.44 | 33.8 | 2079.2 | 150.45 | 156.55 | 162.21 | 0.0459 |

| 630 | 630 | 79.8 | 710 | 54 | 19 | 3.85 | 2.31 | 11.6 | 34.7 | 2366.3 | 191.77 | 202.94 | 213.31 | 0.0459 |

| 710 | 710 | 49.1 | 759 | 45 | 7 | 4.48 | 2.99 | 8.96 | 35.9 | 2343.2 | 169.56 | 176.43 | 182.81 | 0.0407 |

| 710 | 710 | 89.9 | 800 | 54 | 19 | 4.09 | 2.45 | 12.3 | 36.8 | 2666.8 | 216.12 | 228.71 | 240.41 | 0.0407 |

| 800 | 800 | 34.6 | 835 | 72 | 7 | 3.76 | 2.51 | 7.52 | 37.6 | 2480.2 | 167.41 | 172.25 | 176.74 | 0.0361 |

| 800 | 800 | 66.7 | 867 | 84 | 7 | 3.48 | 3.48 | 10.4 | 38.3 | 2732.7 | 205.33 | 214.67 | 224 | 0.0362 |

| 800 | 800 | 101 | 901 | 54 | 19 | 4.44 | 2.61 | 13 | 39.1 | 3004.9 | 243.52 | 257.71 | 270.88 | 0.0362 |

| 900 | 900 | 38.9 | 939 | 72 | 7 | 3.99 | 2.66 | 7.98 | 39.9 | 2790.2 | 188.33 | 193.78 | 198.83 | 0.0321 |

| 900 | 900 | 75 | 975 | 84 | 7 | 3.69 | 3.69 | 11.1 | 40.6 | 3074.2 | 226.5 | 231.75 | 244.5 | 0.0322 |

| 1000 | 1000 | 43.2 | 1043 | 72 | 7 | 4.21 | 2.8 | 8.41 | 42.1 | 3100.3 | 209.26 | 215.31 | 220.93 | 0.0289 |

| 1120 | 1120 | 47.3 | 1167 | 72 | 19 | 4.45 | 1.78 | 8.9 | 44.5 | 3464.9 | 234.53 | 241.15 | 247.77 | 0.0258 |

| 1120 | 1120 | 91.2 | 1211 | 84 | 19 | 4.12 | 2.47 | 12.4 | 45.3 | 3811.5 | 283.17 | 295.94 | 307.79 | 0.0258 |

| 1250 | 1250 | 102 | 1352 | 84 | 19 | 4.35 | 2.61 | 13.1 | 47.9 | 4253.9 | 316.04 | 269.14 | 276.53 | 0.0232 |

| 1250 | 1250 | 52.8 | 1303 | 72 | 19 | 4.7 | 1.88 | 9.4 | 47 | 3867.1 | 261.75 | 330.29 | 343.52 | 0.0231 |

DIN 48206 Standard

| Nominal Cross Section | Cross Section of Steel Wires | Cross Section of Alloy Wires | Number of Alloy Wires | Diameter of Alloy Wires | Number of Steel Wires | Diameter of Steel Wires | Overall Diameter | Linear Mass | Rated Tensile Strength | Max.D.C. Resistance at 20℃ |

| mm² | mm² | mm² | - | mm | - | mm | mm | kg/km | daN | Ω/km |

| 16/2.5 | 15.27 | 2.54 | 6 | 1.8 | 1 | 1.8 | 5.4 | 62 | 748 | 2.18 |

| 25/4 | 23.86 | 3.98 | 6 | 2.25 | 1 | 2.25 | 6.8 | 97 | 1171 | 1.3952 |

| 35/6 | 34.35 | 5.73 | 6 | 2.7 | 1 | 2.7 | 8.1 | 140 | 1685 | 0.9689 |

| 44/32 | 43.98 | 31.67 | 14 | 2 | 7 | 2.4 | 11.2 | 373 | 5027 | 0.7625 |

| 50/8 | 48.25 | 8.04 | 6 | 3.2 | 1 | 3.2 | 9.6 | 196 | 2366 | 0.6898 |

| 50/30 | 51.17 | 29.85 | 12 | 2.33 | 7 | 2.33 | 11.7 | 378 | 5024 | 0.6547 |

| 70/12 | 69.89 | 11.4 | 26 | 1.85 | 7 | 1.44 | 11.7 | 284 | 3399 | 0.4791 |

| 95/15 | 94.39 | 15.33 | 26 | 2.15 | 7 | 1.67 | 13.6 | 383 | 4582 | 0.3547 |

| 95/55 | 96.51 | 56.3 | 12 | 3.2 | 7 | 3.2 | 16 | 714 | 9475 | 0.3471 |

| 105/75 | 105.67 | 75.55 | 14 | 3.1 | 19 | 2.25 | 17.5 | 899 | 12014 | 0.3174 |

| 120/20 | 121.57 | 19.85 | 26 | 2.44 | 7 | 1.9 | 15.5 | 494 | 5914 | 0.2754 |

| 120/70 | 122.15 | 71.25 | 12 | 3.6 | 7 | 3.6 | 18 | 904 | 11912 | 0.2742 |

| 125/30 | 127.92 | 29.85 | 30 | 2.33 | 7 | 2.33 | 16.3 | 590 | 7280 | 0.2621 |

| 150/25 | 148.86 | 24.25 | 26 | 2.7 | 7 | 2.1 | 17.1 | 604 | 7236 | 0.2249 |

| 170/40 | 171.77 | 40.08 | 30 | 2.7 | 7 | 2.7 | 18.9 | 794 | 9775 | 0.1952 |

| 185/30 | 183.78 | 29.85 | 26 | 3 | 7 | 2.33 | 19 | 744 | 8922 | 0.1822 |

| 210/35 | 209.1 | 34.09 | 26 | 3.2 | 7 | 2.49 | 20.3 | 848 | 10167 | 0.1601 |

| 210/50 | 212.06 | 49.48 | 30 | 3 | 7 | 3 | 21 | 979 | 12068 | 0.1581 |

| 230/30 | 230.91 | 29.85 | 24 | 3.5 | 7 | 2.33 | 21 | 674 | 10306 | 0.1449 |

| 240/40 | 243.05 | 39.49 | 26 | 3.45 | 7 | 2.68 | 21.8 | 985 | 11802 | 0.1378 |

| 265/35 | 263.66 | 34.09 | 24 | 3.74 | 7 | 2.49 | 22.4 | 998 | 11771 | 0.1269 |

| 300/50 | 304.26 | 49.48 | 26 | 3.86 | 7 | 3 | 24.5 | 1233 | 14779 | 0.1101 |

| 305/40 | 304.62 | 39.49 | 54 | 2.68 | 7 | 2.68 | 24.1 | 1155 | 13612 | 0.1101 |

| 340/30 | 339.29 | 29.85 | 48 | 3 | 7 | 2.33 | 25 | 1174 | 13494 | 0.0988 |

| 380/50 | 381.7 | 49.48 | 54 | 3 | 7 | 3 | 27 | 1448 | 17056 | 0.0879 |

| 385/35 | 386.04 | 34.09 | 48 | 3.2 | 7 | 2.49 | 26.7 | 1336 | 15369 | 0.0868 |

| 435/55 | 434.29 | 56.3 | 54 | 3.2 | 7 | 3.2 | 28.8 | 1647 | 19406 | 0.0772 |

| 450/40 | 448.71 | 39.49 | 48 | 3.45 | 7 | 2.68 | 28.7 | 1553 | 17848 | 0.0747 |

| 490/65 | 490.28 | 63.55 | 54 | 3.4 | 7 | 3.4 | 30.6 | 1860 | 21907 | 0.0684 |

| 550/70 | 549.65 | 71.25 | 54 | 3.6 | 7 | 3.6 | 32.4 | 2085 | 24560 | 0.061 |

| 560/50 | 561.7 | 49.48 | 48 | 3.86 | 7 | 3 | 32.2 | 1943 | 22348 | 0.0597 |

| 680/85 | 678.58 | 85.95 | 54 | 4 | 19 | 2.4 | 36 | 2564 | 30084 | 0.0494 |

ASTM B711 Standard

| Conductor Area | Alloy Area | Steel Area | No. of Alloy Wires | Dia of Alloy Wire | No. of Steel Wires | Dia of Steel Wire | Dia of Conductor | Linear Weight | Rated Strength * | Maximum DC Resistance at 20 0C |

| mm2 | mm2 | mm2 | mm | mm | mm | Kg/km | daN | ? /km | ||

| 163 | 140 | 23 | 26 | 2.62 | 7 | 2.04 | 16.6 | 560 | 7500 | 0.24 |

| 173 | 140 | 33 | 30 | 2.44 | 7 | 2.44 | 17.1 | 650 | 8740 | 0.24 |

| 186 | 160 | 26 | 26 | 2.8 | 7 | 2.18 | 17.7 | 645 | 8560 | 0.21 |

| 198 | 160 | 38 | 30 | 2.61 | 7 | 2.61 | 18.3 | 740 | 10600 | 0.21 |

| 209 | 180 | 29 | 26 | 2.97 | 7 | 2.31 | 18.8 | 725 | 9510 | 0.187 |

| 222 | 180 | 42 | 30 | 2.76 | 7 | 2.76 | 19.3 | 825 | 11200 | 0.187 |

| 232 | 200 | 32 | 26 | 3.13 | 7 | 2.43 | 19.8 | 800 | 10600 | 0.168 |

| 247 | 200 | 47 | 30 | 2.91 | 7 | 2.91 | 20.4 | 920 | 12400 | 0.168 |

| 260 | 224 | 36 | 26 | 3.31 | 7 | 2.57 | 21 | 900 | 11800 | 0.15 |

| 276 | 224 | 52 | 30 | 3.08 | 7 | 3.08 | 21.6 | 1025 | 13900 | 0.15 |

| 291 | 250 | 41 | 26 | 3.5 | 7 | 2.72 | 22.2 | 1010 | 12900 | 0.135 |

| 308 | 250 | 58 | 30 | 3.26 | 7 | 3.26 | 22.8 | 1145 | 15600 | 0.135 |

| 326 | 280 | 46 | 26 | 3.7 | 7 | 2.88 | 23.4 | 1140 | 14400 | 0.12 |

| 345 | 280 | 65 | 30 | 3.45 | 7 | 3.45 | 24.2 | 1280 | 17100 | 0.12 |

| 367 | 315 | 52 | 26 | 3.93 | 7 | 3.06 | 24.9 | 1276 | 16300 | 0.107 |

| 387 | 315 | 72 | 30 | 3.66 | 19 | 2.2 | 25.6 | 1433 | 19000 | 0.107 |

| 413 | 355 | 58 | 26 | 4.17 | 7 | 3.24 | 26.4 | 1433 | 18300 | 0.095 |

| 436 | 355 | 81 | 30 | 3.88 | 19 | 2.33 | 27.2 | 1614 | 21100 | 0.095 |

| 465 | 400 | 65 | 26 | 4.43 | 7 | 3.45 | 28.1 | 1612 | 20700 | 0.0842 |

| 491 | 400 | 91 | 30 | 4.12 | 19 | 2.47 | 28.8 | 1816 | 23700 | 0.0842 |

| 509 | 450 | 59 | 54 | 3.26 | 19 | 1.96 | 29.5 | 1703 | 21500 | 0.0748 |

| 563 | 500 | 63 | 54 | 3.43 | 19 | 2.06 | 30.9 | 1873 | 22900 | 0.0673 |

| 631 | 560 | 71 | 54 | 3.63 | 19 | 2.18 | 32.7 | 2101 | 25700 | 0.0601 |

| 710 | 630 | 80 | 54 | 3.85 | 19 | 2.31 | 34.6 | 2365 | 28600 | 0.0534 |

| 800 | 710 | 90 | 54 | 4.09 | 19 | 2.45 | 36.8 | 2665 | 32200 | 0.0474 |

| 901 | 800 | 101 | 54 | 4.34 | 19 | 2.6 | 39 | 3000 | 36300 | 0.042 |

| 973 | 900 | 73 | 84 | 3.69 | 19 | 2.21 | 40.6 | 3062 | 35500 | 0.0374 |

| 1081 | 1000 | 81 | 84 | 3.89 | 19 | 2.33 | 42.8 | 3395 | 39100 | 0.0337 |

| 1211 | 1120 | 91 | 84 | 4.12 | 19 | 2.47 | 45.3 | 3803 | 43900 | 0.03 |

| 1352 | 1250 | 102 | 84 | 4.35 | 19 | 2.61 | 47.8 | 4250 | 49000 | 0.027 |

NF C Equal Standard

| Equal steel and Aluminum wire diameter | ||||||||||||||

| Code Name | Al Alloy Area | Steel Wire Area | No. Of Al Alloy Wires | No. Of St | Dia of Wire | Overall Dia of Conductor | Tens Str of Al Alloy | Tens Str of Steel | Rated Str of Conductor | Max DC Resist at 20 0C | Linear Weight | Elasticity Mod * | Coefficient Of Linear Expansion | |

| Mrn2 | mm2 | Wires | mm | mm | hbar | hbar | daN | Ω /km | Kg/km | hbar | / 0C | |||

| PHLOX | 37.7 | 28.27 | 9.42 | 9 | 3 | 2 | 8.3 | 32.4 | 156.8 | 2360 | 1.17 | 155 | 9300 | 17.0 x 10-1 |

| PHLOX | 59.7 | 37.7 | 21.99 | 12 | 7 | 2 | 10 | 32.4 | 156.8 | 4560 | 0.88 | 276 | 10800 | 15.3 x 106 |

| PHLOX | 75.5 | 47.71 | 27.83 | 12 | 7 | 2.25 | 11.25 | 32.4 | 156.8 | 5770 | 0.695 | 348 | 10800 | 15.3 X 10-6 |

| PHLOX | 116.2 | 56.55 | 59.69 | 18 | 19 | 2 | 14 | 32.4 | 156.8 | 10815 | 0.58 | 636 | 12400 | 14.2 x 10-6 |

| PHLOX | 147.1 | 71.57 | 75.54 | 18 | 19 | 2.25 | 15.75 | 32.4 | 156.8 | 13685 | 0.466 | 802 | 12400 | 14.2 X 10-6 |

| PASTEL | 147.1 | 119.28 | 27.83 | 30 | 7 | 2.25 | 15.75 | 32.4 | 156.8 | 8185 | 0.279 | 547 | 8400 | 18.1 x 10-6 |

| PHLOX | 181 | 88.36 | 93.27 | 18 | 19 | 2.5 | 17.5 | 32.4 | 156.8 | 16895 | 0.378 | 990 | 12400 | 14.2 x 10 6 |

| PASTEL | 181.6 | 147.26 | 34.36 | 30 | 7 | 2.5 | 17.5 | 32.4 | 156.8 | 10120 | 0.227 | 675 | 8400 | 18.1 x 10-1 |

| PHLOX | 228 | 110.83 | 116.99 | 18 | 19 | 2.8 | 19.6 | 32.4 | 156.8 | 21200 | 0.3 | 1244 | 12400 | 14.2 x 10-1 |

| PASTEL | 228 | 184.72 | 43.1 | 30 | 7 | 2.8 | 19.6 | 32.4 | 156.8 | 12680 | 0.18 | 848 | 8400 | 18.1 x 101 |

| PHLOX | 288 | 140.28 | 148.07 | 18 | 19 | 3.15 | 22.05 | 32.4 | 156.8 | 26800 | 0.237 | 1570 | 12400 | 14.2 x 101 |

| PASTEL | 288 | 233.8 | 54.55 | 30 | 7 | 3.15 | 22.05 | 32.4 | 156.8 | 16050 | 0.142 | 1074 | 8400 | 18.0 x 101 |

| PASTEL | 299 | 205.17 | 93.27 | 42 | 19 | 2.5 | 22.5 | 32.4 | 156.8 | 20875 | 0.162 | 1320 | 9650 | 16.3 x 10-1 |

| PHLOX | 376 | 147.78 | 227.83 | 24 | 37 | 2.8 | 25.2 | 32.4 | 156.8 | 38960 | 0.225 | 2211 | 13000 | 13.5 x 10-1 |

NF C Non-equal Standard

| Non-equal steel and aluminum wire diameter | |||||||||||||

| Code Name | Totall area | AI Alloy Area | Stell Area | No.&Dia Of Ai Alloy | No.& Dia Of Ai Stell | Overal Dia of Conductor | Tens Str of Al Alloy | Tens Str of Steel | Rated Str of Conductor | Max DC Resist at 20 0C | Linear Weight | Elast Mod * | Coefficient Of Linear Expansion |

| Mm2 | mm² | mm² | wires | wires | mm | hbar | hbar | daN | Ω /km | Kg/km | hbar | */ oC | |

| PHLOX | 94.1 | 51.95 | 42.12 | 15x 2.10 | 19x 1.68 | 12.8 | 32.4 | 156.8 | 8035 | 0.642 | 481 | 11200 | 14.7 x 10 1 |

| PASTEL | 412 | 325.72 | 85.95 | 32x 3.60 | 19x 2.40 | 26.4 | 32.4 | 156.8 | 23830 | 0.103 | 1593 | 8200 | 17.8 x 10-1 |

| PETUNIA | 612 | 507.8 | 104.79 | 66x 3.13 | 19x 2.65 | 32.1 | 32.4 | 156.8 | 32830 | 0.0657 | 2241 | 7750 | 18.6 x 10-1 |

| PETUNIA | 865 | 717.33 | 148.06 | 66x 3.725 | 19x 3.10 | 38.1 | 32.4 | 156.8 | 46000 | 0.0465 | 3174 | 7750 | 18.5 x 10-1 |

| 54x 2.80 | |||||||||||||

| POLYGONM | 1185 | 956.66 | 227.82 | 66x 3.47 | 37x 2.80 | 44.7 | 32.4 | 156.8 | 66385 | 0.0349 | 4475 | 7750 | 18.1 x 10-1 |