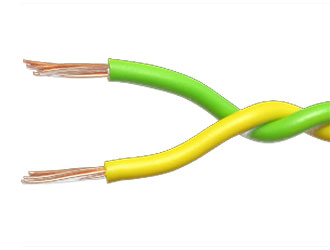

Wires and cables are twisted for several important reasons, mainly to improve performance and durability: 1. Reduction of Electromagnetic Interference (EMI):

1. Reduction of Electromagnetic Interference (EMI):Twisting the wires in a cable helps to cancel out electromagnetic fields that are generated by the current flowing through the wires. This reduces the cable's susceptibility to external electromagnetic interference, which can distort signals, and also minimizes the cable's own emissions of electromagnetic interference that could affect nearby devices.

2. Improved Signal Integrity:Twisted wires help reduce crosstalk, which is interference caused by the electromagnetic fields of adjacent wires affecting each other. By twisting the wires together, these effects are balanced out, leading to more reliable signal transmission, especially important in high-speed data cables.

3. Increased Mechanical Strength:Twisting wires enhances the flexibility and tensile strength of the cable, making it more resistant to physical stress during installation and use. This reduces the likelihood of damage and increases the cable's lifespan.

4. Balanced Electrical Resistance:Twisting helps to evenly distribute the electrical resistance across all wires in the cable. This prevents issues such as localized heating caused by uneven current distribution, ensuring more stable electrical performance.

Effects on Electrical Conductivity and Potential Issues:Electrical Conductivity:Twisting does not significantly impact the overall electrical conductivity of the cable. The wires maintain good contact with each other, ensuring that the cable continues to conduct electricity effectively.

Signal Transmission Quality:For cables used in signal transmission, twisting greatly enhances the quality of the transmitted signals by reducing losses and distortions, ensuring that the signal remains clear and intact over longer distances.

Heat Dissipation:Twisting can slightly increase the surface area of the cable, which might slightly alter heat dissipation characteristics. However, this effect is usually negligible under normal operating conditions.

Manufacturing Complexity and Cost:Twisted cables are more complex to manufacture, which can increase production costs. The process requires precise equipment and techniques, and any inconsistency in twisting can affect the overall performance of the cable.

The benefits of twisting wires and cables, particularly in terms of reducing interference and improving signal integrity, far outweigh any minor drawbacks, making it a crucial design feature in many types of cables.

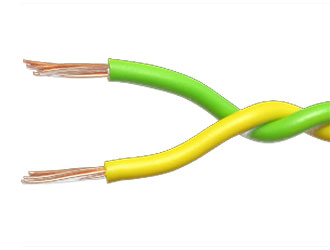

To solve issues related to the twisting of wires and cables, here are a few steps you can take depending on the specific problem you're encountering:1. Problem: Electromagnetic Interference (EMI)Solution: Ensure that the wires are twisted tightly and uniformly throughout the cable. This enhances the cancellation of electromagnetic fields and reduces interference. If EMI is still an issue, consider using shielded cables, where a metal layer surrounds the twisted wires to further block external interference.

2. Problem: Signal Integrity Issues Solution: Verify that the wires are twisted at the appropriate twist rate (the number of twists per unit length). The twist rate should be optimized for the specific signal frequency being transmitted. If crosstalk persists, using cables with a higher twist rate or introducing shielding between pairs of twisted wires might help.

3. Problem: Mechanical DurabilitySolution: If the cable is prone to damage due to physical stress, check that the twisting process has been done correctly and that the wires are not overly twisted or too loosely twisted. Proper twisting improves the cable’s tensile strength and flexibility. Additionally, consider using materials with better durability for the outer insulation.

4. Problem: Uneven Electrical ResistanceSolution: Uneven twisting can lead to inconsistent electrical resistance across the cable. Ensure that the twisting process is uniform and that the wires are of consistent quality and thickness. If this issue persists, it may be necessary to revisit the manufacturing process or choose higher-quality materials.

5. Problem: Heat DissipationSolution: If heat dissipation is a concern, particularly in high-power applications, consider using cables with better thermal management properties. This might include using materials with higher thermal conductivity or designing the cable with additional features like heat sinks or external cooling.

Additional Tips:Testing and Quality Control: Regularly test the cables during and after manufacturing to ensure that they meet the required specifications for twisting, signal integrity, and durability.

Consulting with Experts: If you’re facing persistent issues, consulting with engineers or experts in cable design and manufacturing can help identify and resolve specific problems.

By carefully analyzing the specific issue and implementing targeted solutions, you can effectively address problems related to the twisting of wires and cables.

Get a free quote by E-mail:info@cable-uni.com