Our overhead transmission line cables are engineered for efficient, long-distance power transmission. With high-strength materials and advanced manufacturing processes, our cables offer unparalleled reliability and durability. Designed for use in a wide range of applications, these cables are ideal for urban power networks, remote transmission systems, and high-voltage power lines.

Aluminum Cables Steel Reinforced (ACSR)

ACSR (Aluminum Conductor Steel Reinforced) is constructed by stranding aluminum wire around a core zinc-coated steel cable. Although its conductivity is lower than that of copper wires, ACSR offers several advantages, including reduced weight and increased tensile strength due to the steel core. The larger external diameter compared to copper wires contributes to excellent corona characteristics, which are particularly useful in high-voltage transmission lines. ACSR is typically used for overhead power transmission lines with voltages above 154kV, especially in long-distance applications between major transmission points.

Aluminum Cables Steel Reinforced/Aluminum Wire (ACSR/AW)

ACSR/AW (Aluminum Conductor Steel Reinforced/Aluminum Wire) is made by stranding aluminum wire around a core zinc-coated steel cable. Similar to ACSR, it offers the benefits of reduced weight and higher tensile strength, but with slightly enhanced corrosion resistance due to the aluminum wire. While the conductivity of ACSR/AW is lower than copper wire, it is still suitable for high-voltage transmission lines where reduced line sag and excellent corona characteristics are necessary. ACSR/AW is commonly used in overhead power transmission lines exceeding 154kV, particularly for long-distance or high-stress applications.

In addition to the standard ACSR/AW, some variants use high-strength, super-thermal resistant aluminum alloys for enhanced performance in extreme temperatures and environmental conditions.

High-Strength Super Thermal-Resistant Aluminum Alloy Conductor Aluminum-Clad Invar Reinforced (HSTACIR/AW)

HSTACIR/AW is an advanced conductor made by stranding super thermal-resistant aluminum alloy around a zinc-plated invar line. Invar is a thermally treated alloy made by adding small amounts of zirconium (Zr) to the aluminum, which significantly enhances its properties. The allowable current is approximately twice the capacity of conventional hard-drawn aluminum wires, while conductivity remains at around 60%.

This conductor is specifically designed for overhead transmission lines in areas where resistance to corrosion, including electrolytic (galvanic) corrosion, is critical—such as in coastal regions. The enhanced sag properties of the invar core ensure minimal line sag even in high-temperature and high-stress environments. HSTACIR/AW is ideal for areas requiring exceptional durability and corrosion resistance.

Super Thermal-Resistant Aluminum Alloy Conductors Aluminum-Clad Invar Reinforced (STACIR)

STACIR is a similar conductor to HSTACIR/AW but uses a zinc-coated invar line as the core. This product is particularly well-suited for applications where double the current capacity of ACSR is required without the need to replace existing steel towers. STACIR can carry up to twice the amount of current compared to ACSR, offering enhanced performance while maintaining the same physical structure.

The use of super-thermal resistant aluminum alloy and the zinc-plated invar core ensures that STACIR cables have superior performance in areas where high capacity and corrosion resistance are critical. This conductor is often used to replace ACSR, as it is less expensive to install and provides a higher capacity without the need for significant infrastructure changes.

Thermal-Resistant Aluminum Cables Steel Reinforced (TACSR)

TACSR (Thermal-Resistant Aluminum Conductor Steel Reinforced) is constructed by stranding thermal-resistant aluminum wire around a zinc-coated steel cable. It offers improved performance over standard ACSR, with an allowable current approximately 1.5 to 1.6 times that of conventional ACSR, resulting in higher efficiency. The thermal resistance of the aluminum allows the conductor to perform in temperatures up to 150°C.

TACSR is ideal for applications in regions where high temperatures are common, providing reliable performance in extreme conditions. This conductor is often used in lightweight transmission line installations where enhanced temperature resistance is needed.

Thermal-Resistant Aluminum Cables Steel Reinforced/Aluminum Wire (TACSR/AW)

TACSR/AW combines the benefits of TACSR with an aluminum-coated steel core, providing improved corrosion resistance. The thermal-resistant aluminum wire offers a significant performance advantage, allowing the conductor to operate in environments with temperatures reaching up to 150°C. The increased allowable current (approximately 1.5 to 1.6 times that of ACSR) and the lower electrical resistance make this conductor a superior choice for areas requiring high-efficiency power transmission lines.

TACSR/AW offers improved lifespan and significantly enhanced electrical properties, making it an ideal solution for areas with high temperature variations or corrosive environments. The corrosion-resistant design also ensures that the conductor remains reliable over time, reducing maintenance needs and improving overall system efficiency.

Key Features:

- High Strength: Our overhead transmission line cables are designed to withstand high tensile loads, ensuring long-lasting performance even in harsh conditions.

- Electromagnetic Interference Resistance: Superior resistance to electrical interference ensures stable and uninterrupted power transmission.

- Corrosion Resistance: Made from corrosion-resistant materials, these cables are highly durable and perform well in challenging environmental conditions, such as high humidity or saltwater exposure.

- High-Temperature Performance: With the ability to withstand high operating temperatures, these cables ensure efficient power transfer in hot climates.

- Weather Resistance: The cables are built to endure extreme weather conditions, including strong winds, heavy rainfall, and direct UV exposure.

Applications:

Our overhead transmission line cables are suitable for a wide range of applications, including:

- Urban Power Networks: Providing stable power delivery to cities and industrial zones, ensuring reliable service for all types of businesses and residential areas.

- Long-Distance Power Transmission: Designed for high-efficiency power transfer over long distances, minimizing energy loss and ensuring reliable delivery.

- Renewable Energy Projects: Perfect for connecting wind and solar power generation systems to the main power grid, helping to deliver clean energy.

- High-Voltage Transmission: Essential for high-voltage power lines, ensuring reliable power transfer even in extreme conditions.

Parameter

Aluminum Conductor Steel Reinforced (ACSR)IEC 61089(A1/S1A)

|

Nom. Size |

Construction |

Calculated Aluminum Area |

Approx. Diameter |

Standard Weight |

Calculated Breaking Load |

Calculated D.C Resistance at 20℃ |

Current Carrying Capacity |

|

|

Aluminum |

Steel |

|||||||

|

㎟ |

Nos./㎜ |

㎟ |

㎜ |

㎏/㎞ |

kN |

Ϊ/㎞ |

A |

|

|

16 |

6/1.84 |

1/1.84 |

16.0 |

5.53 |

64.6 |

60.8 |

1.7934 |

100 |

|

25 |

6/2.30 |

1/2.30 |

25.0 |

6.91 |

100.9 |

9.13 |

1.1478 |

133 |

|

40 |

6/2.91 |

1/2.91 |

40.0 |

8.74 |

161.5 |

14.40 |

0.7174 |

180 |

|

63 |

6/3.66 |

1/3.66 |

63.1 |

11.0 |

254.4 |

21.63 |

0.4555 |

240 |

|

100 |

6/4.61 |

1/4.61 |

100.1 |

13.8 |

403.8 |

34.33 |

0.2869 |

322 |

|

125 |

18/2.97 |

1/2.97 |

124.7 |

14.9 |

397.9 |

29.17 |

0.2304 |

381 |

|

125 |

26/2.47 |

7/192 |

124.6 |

15.7 |

503.9 |

45.69 |

0.2310 |

387 |

|

160 |

18/3.36 |

1/3.36 |

159.6 |

16.8 |

509.3 |

36.18 |

0.1800 |

446 |

|

160 |

26/2.80 |

7/2.28 |

160.1 |

17.7 |

644.9 |

57.69 |

0.1805 |

452 |

|

200 |

18/3.76 |

1/3.76 |

199.9 |

18.8 |

636.7 |

44.22 |

0.1440 |

515 |

|

200 |

26/3.13 |

7/2.43 |

200.1 |

19.8 |

806.2 |

70.13 |

0.1444 |

522 |

|

250 |

22/3.08 |

7/2.11 |

249.5 |

21.6 |

880.6 |

68.72 |

0.1154 |

598 |

|

250 |

26/3.50 |

7/2.72 |

250.1 |

22.2 |

1,007.7 |

87.67 |

0.1155 |

602 |

|

315 |

45/2.99 |

7/1.99 |

316.0 |

23.9 |

1,039.6 |

79.03 |

0.0917 |

689 |

|

315 |

26/3.93 |

7/3.05 |

315.4 |

24.9 |

1,269.7 |

106.83 |

0.0917 |

698 |

|

400 |

45/3.36 |

7/2.24 |

399.0 |

26.9 |

1,320.1 |

98.36 |

0.0722 |

790 |

|

400 |

54/3.07 |

7/3.07 |

399.7 |

27.6 |

1,510.3 |

123.04 |

0.0723 |

797 |

|

450 |

45/3.57 |

7/2.38 |

450.4 |

28.5 |

1,485.2 |

107.47 |

0.0642 |

851 |

|

450 |

54/3.26 |

7/3.26 |

450.7 |

29.3 |

1,699.1 |

138.42 |

0.0643 |

859 |

|

500 |

45/3.76 |

7/2.51 |

499.7 |

30.1 |

1,650.2 |

119.41 |

0.0578 |

911 |

|

500 |

54/3.43 |

7/3.43 |

499.0 |

30.9 |

1,887.9 |

153.80 |

0.0578 |

919 |

|

560 |

45/3.98 |

7/2.65 |

559.8 |

31.8 |

1,848.2 |

133.74 |

0.0516 |

978 |

|

560 |

54/3.63 |

19/2.18 |

558.9 |

32.7 |

2,103.4 |

172.59 |

0.0516 |

988 |

|

630 |

45/4.22 |

7/2.81 |

629.4 |

33.8 |

2,079.2 |

150.45 |

0.0459 |

1,053 |

|

630 |

54/3.85 |

19/2.31 |

628.6 |

34.7 |

2,366.3 |

191.77 |

0.0459 |

1,064 |

|

710 |

45/4.48 |

7/2.99 |

709.3 |

35.9 |

2,343.2 |

169.56 |

0.0407 |

1,135 |

|

710 |

54/4.09 |

19/2.45 |

709.5 |

36.8 |

2,666.8 |

216.12 |

0.0407 |

1,147 |

|

800 |

54/4.34 |

19/2.61 |

798.8 |

39.1 |

3,004.9 |

243.52 |

0.0362 |

1,235 |

ASTM B 232

|

Code Name |

Nom. Size |

Construction |

Calculated Aluminum Area |

Approx. Diameter |

Standard Weight |

Calculated Breaking Load |

Calculated D.C Resistance at 20℃ |

Current Carrying Capacity |

|

|

Aluminum |

Steel |

||||||||

|

- |

AWG/MCM |

Nos./㎜ |

㎟ |

㎜ |

㎏/㎞ |

kgf |

Ϊ/㎞ |

A |

|

|

Turkey |

6 |

6/1.679 |

1/1.679 |

13.28 |

5.04 |

53.67 |

539.94 |

2.1595 |

89 |

|

Swan |

4 |

6/2.118 |

1/2.118 |

21.14 |

6.35 |

85.41 |

844.71 |

1.3571 |

120 |

|

Sparrow |

2 |

6/2.672 |

1/2.672 |

33.64 |

8.02 |

135.93 |

1,291.73 |

0.8527 |

161 |

|

Robin |

1 |

6/3.000 |

1/3.000 |

42.41 |

9.00 |

171.35 |

1,615.87 |

0.6764 |

186 |

|

Raven |

1/0 |

6/3.371 |

1/3.371 |

53.55 |

10.11 |

216.35 |

1,984.35 |

0.5357 |

216 |

|

Quail |

2/0 |

6/3.782 |

1/3.782 |

67.40 |

11.35 |

272.33 |

2,400.98 |

0.4256 |

250 |

|

Pigeon |

3/0 |

6/4.247 |

1/4.247 |

85.00 |

12.74 |

343.41 |

2,994.40 |

0.3375 |

290 |

|

Penguin |

4/0 |

6/4.770 |

1/4.770 |

107.22 |

14.31 |

433.19 |

3,777.31 |

0.2676 |

337 |

|

Waxwing |

266.8 |

18/3.091 |

1/3.091 |

135.07 |

15.46 |

430.78 |

3,113.00 |

0.2134 |

400 |

|

Partridge |

266.8 |

26/2.573 |

7/2.002 |

135.19 |

16.30 |

546.67 |

5,118.90 |

0.2143 |

406 |

|

Ostrich |

300 |

26/2.728 |

7/2.121 |

151.97 |

17.28 |

614.23 |

5,749.42 |

0.1906 |

437 |

|

Merlin |

336.4 |

18/3.472 |

1/3.472 |

170.42 |

17.36 |

543.52 |

3,927.72 |

0.1692 |

464 |

|

Linnet |

336.4 |

26/2.888 |

7/2.245 |

170.32 |

18.29 |

688.31 |

6,393.91 |

0.1701 |

470 |

|

Oriole |

336.4 |

30/2.690 |

7/2.690 |

170.50 |

18.83 |

784.58 |

7,876.39 |

0.1703 |

474 |

|

Chikadee |

397.5 |

18/3.774 |

1/3.774 |

201.36 |

18.87 |

642.18 |

4,506.82 |

0.1432 |

516 |

|

Brant |

397.5 |

24/3.269 |

7/2.179 |

201.43 |

19.61 |

761.98 |

6,630.92 |

0.1438 |

521 |

|

Ibis |

397.5 |

26/3.139 |

7/2.441 |

201.21 |

19.88 |

813.34 |

7,384.19 |

0.1440 |

523 |

|

Lark |

397.5 |

30/2.924 |

7/2.924 |

201.45 |

20.47 |

927.02 |

9,249.01 |

0.1442 |

527 |

|

Pelican |

477.0 |

18/4.135 |

1/4.135 |

241.72 |

20.68 |

770.91 |

5,318.59 |

0.1193 |

580 |

|

Flicker |

477.0 |

24/3.581 |

7/2.388 |

241.72 |

21.49 |

914.59 |

7,799.74 |

0.1199 |

586 |

|

Hawk |

477.0 |

26/3.439 |

7/2.675 |

241.51 |

21.78 |

976.40 |

8,865.69 |

0.1200 |

588 |

|

Hen |

477.0 |

30/3.203 |

7/3.203 |

241.73 |

22.42 |

1,112.37 |

10,785.80 |

0.1201 |

592 |

|

Osprey |

556.5 |

18/4.465 |

1/4.465 |

281.84 |

22.33 |

898.87 |

6,201.38 |

0.1023 |

640 |

|

Parakeet |

556.5 |

24/3.868 |

7/2.578 |

282.02 |

23.21 |

1,066.76 |

8,988.20 |

0.1027 |

646 |

|

Dove |

556.5 |

26/3.716 |

7/2.891 |

281.98 |

23.54 |

1,140.16 |

10,273.35 |

0.1027 |

649 |

|

Eagle |

556.5 |

30/3.459 |

7/3.459 |

281.91 |

24.21 |

1,297.28 |

12,578.81 |

0.1030 |

654 |

|

Peacock |

605.0 |

24/4.034 |

7/2.690 |

306.74 |

24.21 |

1,160.60 |

9,781.27 |

0.0944 |

682 |

|

Squab |

605.0 |

26/3.874 |

7/3.012 |

306.47 |

24.53 |

1,238.68 |

11,141.36 |

0.0945 |

685 |

|

Teal |

605.0 |

30/3.607 |

19/2.164 |

306.55 |

25.25 |

1,398.33 |

13,589.86 |

0.0947 |

689 |

|

Kingbird |

636.0 |

18/4.775 |

1/4.775 |

322.34 |

23.88 |

1,028.02 |

7,092.38 |

0.0894 |

697 |

|

Rook |

636.0 |

24/4.135 |

7/2.756 |

322.29 |

24.81 |

1,219.12 |

10,273.07 |

0.0899 |

704 |

|

Grosbeak |

636.0 |

26/3.973 |

7/3.089 |

322.33 |

25.16 |

1,302.81 |

11,407.67 |

0.0899 |

707 |

|

Egret |

636.0 |

30/3.698 |

19/2.220 |

322.21 |

25.89 |

1,470.50 |

14,295.77 |

0.0901 |

712 |

|

Flamingo |

666.6 |

24/4.234 |

7/2.822 |

337.91 |

25.40 |

1,278.20 |

10,769.89 |

0.0857 |

726 |

|

Gannet |

666.6 |

26/4.067 |

7/3.162 |

337.76 |

25.75 |

1,365.16 |

11,953.50 |

0.0858 |

728 |

ASTM B 232

|

Code Name |

Nom. Size |

Construction |

Calculated Aluminum Area |

Approx. Diameter |

Standard Weight |

Calculated Breaking Load |

Calculated D.C Resistance at 20℃ |

Current Carrying Capacity |

|

|

Aluminum |

Steel |

||||||||

|

- |

AWG/MCM |

Nos./㎜ |

㎟ |

㎜ |

㎏/㎞ |

kgf |

Ϊ/㎞ |

A |

|

|

Stilt |

715.5 |

24/4.387 |

7/2.924 |

362.77 |

26.32 |

1,372.25 |

11,562.41 |

0.0799 |

759 |

|

Starling |

715.5 |

26/4.214 |

7/3.277 |

362.62 |

26.69 |

1,465.83 |

12,836.33 |

0.0799 |

762 |

|

Redwing |

715.5 |

30/3.922 |

19/2.352 |

362.43 |

27.45 |

1,652.69 |

15,686.33 |

0.0801 |

767 |

|

Cuckoo |

795.0 |

24/4.623 |

7/3.081 |

402.86 |

27.74 |

1,523.79 |

12,634.33 |

0.0719 |

811 |

|

Drake |

795.0 |

26/4.442 |

7/3.454 |

402.92 |

28.13 |

1,628.65 |

14,261.54 |

0.0719 |

815 |

|

Tern |

795.0 |

45/3.376 |

7/2.250 |

402.82 |

27.01 |

1,333.44 |

9,995.01 |

0.0719 |

793 |

|

Condor |

795.0 |

54/3.081 |

7/3.081 |

402.59 |

27.73 |

1,522.66 |

12,756.23 |

0.0720 |

800 |

|

Mallard |

795.0 |

30/4.135 |

19/2.482 |

402.87 |

28.95 |

1,838.39 |

17,456.77 |

0.0721 |

820 |

|

Ruddy |

900.0 |

45/3.592 |

7/2.395 |

456.01 |

28.74 |

1,509.74 |

11,098.94 |

0.0635 |

858 |

|

Canary |

900.0 |

54/3.279 |

7/3.279 |

456.00 |

29.51 |

1,724.65 |

14,448.47 |

0.0635 |

866 |

|

Rail |

954.0 |

45/3.698 |

7/2.466 |

483.32 |

29.59 |

1,600.23 |

11,764.77 |

0.0599 |

891 |

|

Cardinal |

954.0 |

54/3.376 |

7/3.376 |

483.38 |

30.38 |

1,828.20 |

15,315.95 |

0.0599 |

899 |

|

Ortolan |

1033.5 |

45/3.848 |

7/2.565 |

523.33 |

30.78 |

1,732.45 |

12,540.73 |

0.0554 |

836 |

|

Curlew |

1033.5 |

54/3.513 |

7/3.513 |

523.41 |

31.62 |

1,979.59 |

16,584.23 |

0.0553 |

946 |

|

Bluejay |

1113.0 |

45/3.995 |

7/2.664 |

564.07 |

31.96 |

1,867.58 |

13,520.90 |

0.0514 |

981 |

|

Finch |

1113.0 |

54/3.647 |

19/2.189 |

564.10 |

32.83 |

2,120.85 |

17,723.45 |

0.0516 |

986 |

|

Bunting |

1192.5 |

45/4.135 |

7/2.756 |

604.30 |

33.08 |

2,000.44 |

14,480.00 |

0.0479 |

1,025 |

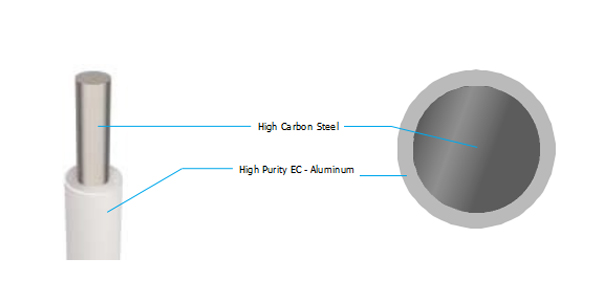

Aluminum Clad Steel Wire (AW)

20.3(%IACS)

|

Nom. Diameter |

Min. Tensile Strength |

Nom. Weight |

Max. D.C Resistance at 20℃ |

Min. Thickness of Aluminum |

Nom. Cross-Sectional Area |

|

㎜ |

㎏/㎟ |

㎏/㎞ |

Ϊ/㎞ |

㎜ |

㎟ |

|

2.0 |

137 |

20.71 |

27.0344 |

0.10 |

3.15 |

|

2.2 |

137 |

25.06 |

22.3425 |

0.11 |

3.81 |

|

2.4 |

137 |

29.82 |

18.7739 |

0.12 |

4.53 |

|

2.5 |

137 |

32.35 |

17.3020 |

0.12 |

4.91 |

|

2.7 |

137 |

37.74 |

14.8337 |

0.13 |

5.73 |

|

2.9 |

137 |

43.53 |

12.8582 |

0.14 |

6.61 |

|

3.0 |

137 |

46.59 |

12.0153 |

0.15 |

7.07 |

|

3.2 |

137 |

53.01 |

10.5603 |

0.16 |

8.05 |

|

3.3 |

135 |

56.37 |

9.9300 |

0.16 |

8.56 |

|

3.5 |

135 |

63.41 |

8.8276 |

0.17 |

9.63 |

|

3.6 |

135 |

67.08 |

8.3440 |

0.18 |

10.18 |

|

3.8 |

135 |

74.74 |

7.4888 |

0.19 |

11.35 |

|

4.0 |

135 |

82.82 |

6.7586 |

0.20 |

12.57 |

|

4.2 |

135 |

91.31 |

6.1303 |

0.21 |

13.86 |

|

Nom. Diameter |

Min. Tensile Strength |

Nom. Weight |

Max. D.C Resistance at 20℃ |

Min. Thickness of Aluminum |

Nom. Cross-Sectional Area |

|

㎜ |

㎏/㎟ |

㎏/㎞ |

Ϊ/㎞ |

㎜ |

㎟ |

|

2.0 |

110 |

18.57 |

20.3529 |

0.14 |

3.15 |

|

2.2 |

110 |

22.47 |

16.7982 |

0.15 |

3.81 |

|

2.4 |

110 |

26.74 |

14.1152 |

0.16 |

4.53 |

|

2.5 |

110 |

29.02 |

13.0086 |

0.17 |

4.91 |

|

2.7 |

110 |

33.84 |

11.1528 |

0.18 |

5.73 |

|

2.9 |

110 |

39.04 |

9.6675 |

0.20 |

6.61 |

|

3.0 |

110 |

41.78 |

9.0337 |

0.21 |

7.07 |

|

3.2 |

110 |

47.54 |

7.9398 |

0.22 |

8.05 |

|

3.3 |

110 |

50.55 |

7.4659 |

0.23 |

8.56 |

|

3.5 |

110 |

56.87 |

6.6370 |

0.24 |

9.63 |

|

3.6 |

110 |

60.16 |

6.2734 |

0.25 |

10.18 |

|

3.8 |

110 |

67.03 |

5.6305 |

0.26 |

11.35 |

|

4.0 |

110 |

74.27 |

5.0815 |

0.28 |

12.57 |

|

4.2 |

110 |

81.88 |

4.6091 |

0.29 |

13.86 |

|

4.5 |

110 |

94.00 |

4.0150 |

0.30 |

15.91 |

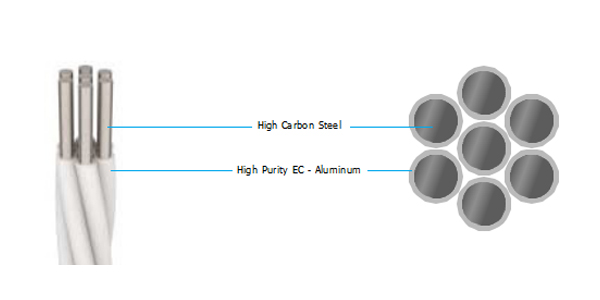

Stranded Aluminum Clad Steel Conductor (AWS)

ASTM B 416

|

Nom. Size |

Stranding |

Nom. Overall Diameter |

Breaking Load |

Nom. Weight |

Max. D.C Resistance at 20℃ |

Nom. Cross-Sectional Area |

|

AWG |

Nos./㎜ |

㎜ |

kgf |

㎏/㎞ |

Ϊ/㎞ |

㎟ |

|

37/5 |

37/4.620 |

32.36 |

64,770 |

4170 |

0.1394 |

620.6 |

|

37/6 |

37/4.115 |

28.70 |

54,520 |

3307 |

0.1758 |

492.2 |

|

37/7 |

37/3.665 |

25.65 |

45,670 |

2622 |

0.2216 |

390.3 |

|

37/8 |

37/3.264 |

22.83 |

38,190 |

2080 |

0.2794 |

309.5 |

|

37/9 |

37/2.906 |

20.35 |

30,250 |

1649 |

0.3524 |

245.5 |

|

37/10 |

37/2.588 |

18.11 |

24,010 |

1308 |

0.4443 |

194.6 |

|

19/5 |

19/4.620 |

23.11 |

33,270 |

2128 |

0.2699 |

318.7 |

|

19/6 |

19/4.114 |

20.57 |

27,980 |

1688 |

0.3403 |

252.7 |

|

19/7 |

19/3.665 |

18.31 |

23,460 |

1339 |

0.4292 |

200.4 |

|

19/8 |

19/3.264 |

16.31 |

19,610 |

1062 |

0.5411 |

159.0 |

|

19/9 |

19/2.906 |

14.53 |

15,550 |

842.0 |

0.6821 |

126.1 |

|

19/10 |

19/2.588 |

12.93 |

12,330 |

667.8 |

0.8603 |

99.93 |

|

7/5 |

7/4.620 |

13.87 |

12,260 |

781.2 |

0.7428 |

117.4 |

|

7/6 |

7/4.115 |

12.34 |

10,310 |

619.5 |

0.9197 |

93.09 |

|

7/7 |

7/3.665 |

11.00 |

8,645 |

491.1 |

1.1598 |

73.87 |

|

7/8 |

7/3.264 |

9.779 |

7,225 |

389.6 |

1.4627 |

58.56 |

|

7/9 |

7/2.906 |

8.702 |

5,728 |

308.9 |

1.8442 |

46.44 |

|

7/10 |

7/2.588 |

7.772 |

4,544 |

245.1 |

2.3255 |

36.82 |

|

7/11 |

7/2.304 |

6.909 |

3,603 |

194.4 |

2.9325 |

29.18 |

|

7/12 |

7/2.052 |

6.147 |

2,858 |

154.2 |

3.6976 |

23.16 |

Why Choose Our Overhead Transmission Line Cables?

- Proven Durability: Our cables are built to last, offering more than 30 years of reliable performance, even in the toughest environments.

- Advanced Manufacturing: Our cables are manufactured using the latest technologies and high-quality materials to ensure the highest standards of performance.

- Global Certification: Our products meet international standards, including those set by the International Electrotechnical Commission (IEC), ensuring global compliance and safety.

- Flexible Solutions: We offer a range of voltage and conductor sizes to suit different power transmission needs, from urban distribution to long-distance, high-voltage lines.

FAQ:

-

Q: Are the overhead transmission line cables suitable for extreme weather conditions?

A: Yes, our cables are designed to withstand extreme weather conditions, including high winds, heavy rain, and UV exposure. -

Q: What is the lifespan of the overhead transmission line cables?

A: These cables are designed to last for more than 30 years under normal operating conditions, providing long-term reliability. -

Q: Can the cables be customized for specific voltage and diameter requirements?

A: Yes, we offer customization options to meet your specific voltage, diameter, and length requirements for different power transmission systems.

Get in Touch:

Interested in learning more or requesting a quote?

Contact us today to get detailed information and discuss how our overhead transmission line cables can meet your power transmission needs.

Request a Quote: info@cable-uni.com