Mining cables are specialized cables designed for use in harsh underground environments such as coal mines and metal mines. These flame-retardant, flexible, and high-strength cables are widely used for powering and connecting underground equipment like shearers, conveyors, drilling machines, underground substations, communication, and lighting systems.

Built with safety and durability in mind, all mining cables must be certified by the National Center for Safety Mark of Mining Products (MA certification) and comply with stringent flame-retardancy and mechanical performance standards.

Our mining cables comply with the following international and national standards:

GB/T12972-2008 – Rubber Sheathed Flexible Cables for Mining

MT818-2009 – Flame-Retardant Cables for Coal Mines

IEC, BS, DIN, UL standards are also available upon request for export orders

300/500V, 380/660V, 660/1140V, 1.9/3.3kV, 3.6/6kV, 6/10kV, 8.7/10kV

Temperature Resistance: Max operating temperature 65°C to 90°C

Low Temperature Flexibility: Operable in -35°C environments

Small Bending Radius: As low as 6× cable outer diameter

Reinforced Structure: Strong anti-abrasion and anti-torsion design for frequent movement

Enhanced Flame Retardancy: Self-extinguishing after fire source removal

Color-coded Outer Sheath: For quick voltage level identification underground

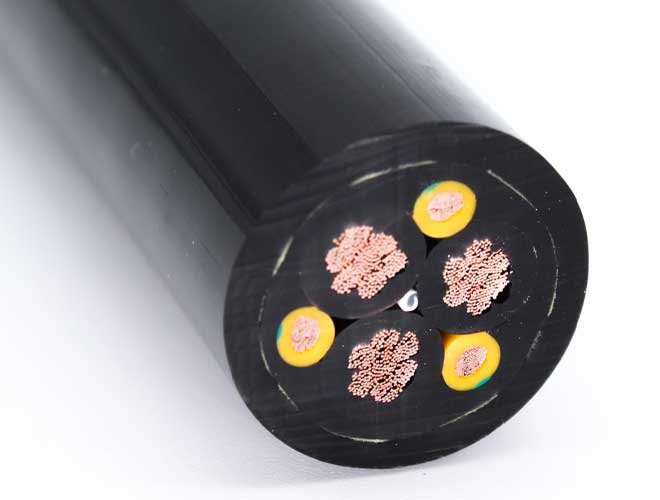

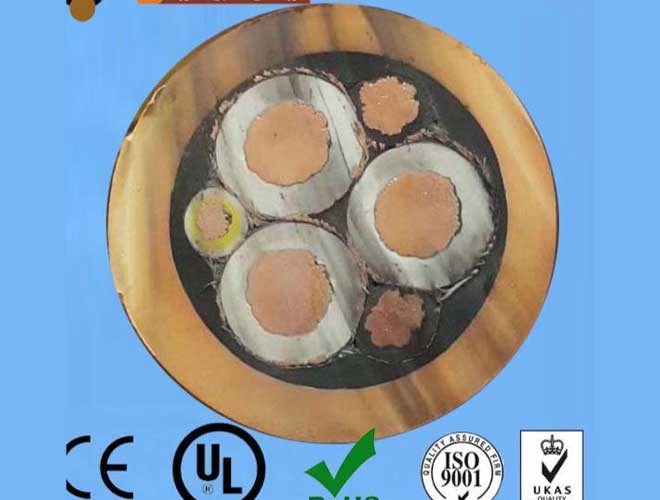

Conductors: High-purity copper, stranded flexible (Class 5 or Class 6)

Insulation: Ethylene-propylene rubber or cross-linked polyethylene

Shielding: Braided copper or steel wire shielding (optional)

Armor: Steel wire or tape for mechanical protection (optional)

Outer Jacket: Heavy-duty rubber or flame-retardant PVC

| Model | Application |

| MC, MCP | Power supply for mobile mining equipment |

| MY, MYQ | Underground fixed or semi-mobile equipment |

| MCPTJ, MYPTJ | Shearer and mining machine cables |

| MHYV, MHYVP | Communication signal transmission |

| MHYVRP, MHYBV | Shielded and armored signal cables |

| UGF Cable | 10kV High voltage underground power cables |

| YQ, YQW, YZ, YZW, YC, YCW | Light/medium/heavy-duty rubber cables for mobile electrical equipment |

By Structure: Rubber sheathed cables, Armored cables, Plastic insulated cables

By Function: Power cables, Control cables, Signal & Communication cables

By Voltage: Low Voltage (≤1kV), Medium Voltage (1kV–10kV)

By Core Material: Copper Core, Aluminum Core

Underground coal mining machinery

Drilling equipment and mining drills

Underground power supply and mobile substations

Mine lighting and communication systems

Cap lamp and signal cable systems

High safety performance in explosive or dusty environments

Strong flexibility and resistance to bending, stretching, and torsion

Excellent abrasion resistance and oil resistance

Long service life for fixed-use cables (up to 10+ years)

Customizable designs and OEM/ODM support available

| Cable Type | Typical Lifespan |

| Fixed Power & Control Cables (MYV, MKYJV) | 10+ years |

| Shearer Cables (MCPTJ) | 6 months to 1 year |

| Flexible Mining Cables (MYPTJ) | Around 1 year |

Ensure safe cable routing to avoid interference with underground structures

Plan cable length economically to control installation and maintenance costs

Maintain adequate repair and inspection access to critical cable sections

Replace worn cables in time to ensure operational safety

Mining Cable vs. Regular Cables

| Feature | Mining Cable | Standard Cable |

| Structure | Reinforced, multi-layer armored | Simple PVC or rubber jacket |

| Environment | Harsh, wet, corrosive, explosive | General industrial environments |

| Safety Requirements | Flame-retardant, anti-explosion | Basic safety ratings |

| Application Flexibility | Frequent bending, mobility | Mostly fixed installation |

MA-certified, tested under real coal mine conditions

High-performance materials and strict quality control

Competitive factory prices for global customers

Contact Us for Mining Cable Solutions

Looking for reliable underground mining cable or flame-retardant flexible cables for coal mine applications? Contact our expert team to get a quote or technical recommendation.

Email: info@cable-uni.com

Website: https://cable-uni.com/

WhatsApp: +86-18625541622