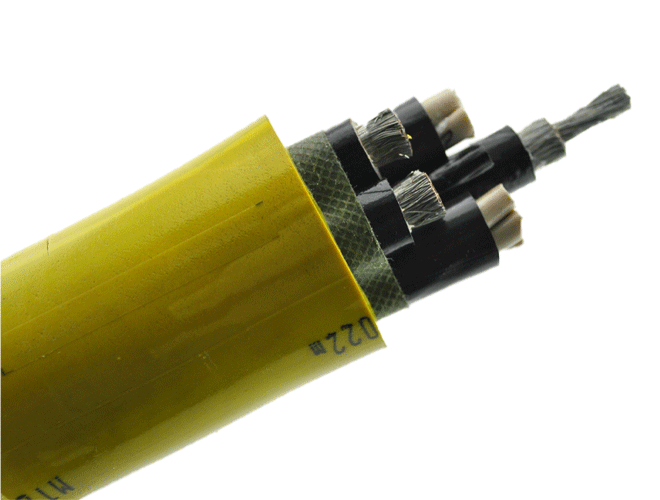

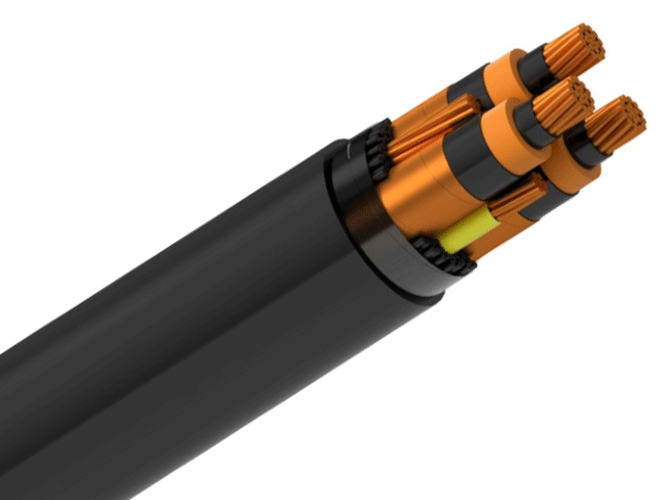

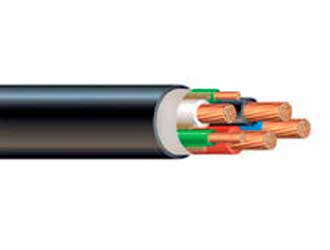

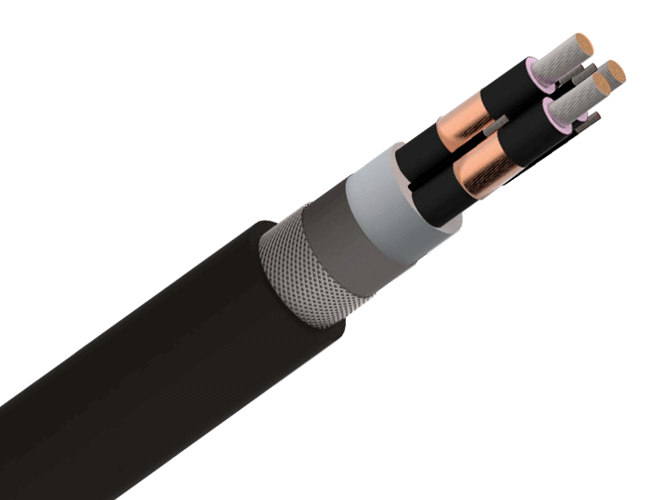

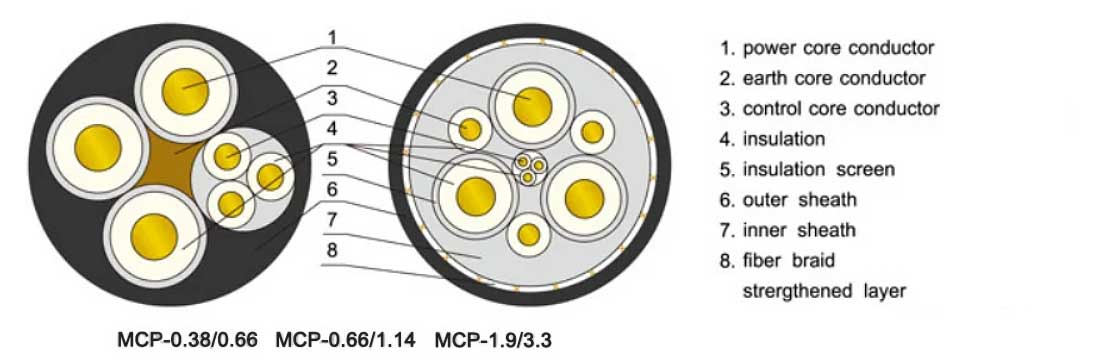

Flexible screen rubber sheathed Coalcutter Cables MCP-1.9/3.3 kV

Application:

Electrical connection of coalcutter and similar equipments.

Manufacturing standard:

MT818.2

Service Property Parameter:

1. Rated voltage U0/U 0.38/0.66kV, 0.66/1.14kV, 1.9/3.3kV.

2. The max temperature of conductor in normal operation is 65℃.

3. The minimum-bending radius of cable is 6 times of cable diameter.

4. Cables with yellow sheath can't be exposed directly in the sunlight for long time.

Type & Description:

| Type | Description |

|---|---|

| MC-0.38/0.66kV | Flexible rubber-sheathed coalcutter cables |

| MCP-0.38/0.66kV | Flexible sceened rubber-sheathed coalcutter cables |

| MCP-0.66/1.14kV | Flexible sceened rubber-sheathed coalcutter cables |

| MCP-1.9/3.3kV | Flexible sceened rubber-sheathed coalcutter cables |

Main technical indexes:

1. 20'℃ D.C conductor resistance shall comply with thestipulations of GB/T3956

2. Insulation resistance should comply with the stiputations in the table.

| Core type | Cross section area mm² | 20℃ insulation resistance | |

|---|---|---|---|

| Rated voltage up to 0.66/1.14kV | Rated voltage 1.9/3.3kV | ||

| Power core | 16 | ≥120 | --- |

| 25 | ≥120 | --- | |

| 35 | ≥100 | ≥380 | |

| 50 | ≥100 | ≥350 | |

| 70 | ≥80 | ≥320 | |

| 95 | ≥80 | ≥280 | |

| Control core | --- | ≥100 | ≥100 |

3. Voltage test should comply with the stipulations in the table

| Insulation core type | Rated voltage U0U(kV) | Power frequenay test voltage(kV) | Test time(min) |

|---|---|---|---|

| Power core | 0.38/0.66 | 3.0 | 5 |

| 0.66/1.14 | 3.7 | 5 | |

| 1.9/3.3 | 6.8 | 5 | |

| Control core | --- | 1.5 | 5 |

4. Flame retardance test:The methods of test and requiremenis shall be those specified in MT386.

| MC-0.38/0.66 & MCP-0.38/0.66 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| No.of cores x section area (mm²) | Nominal thickness(mm) | Outer diameter of cable(mm) | Weight for reference kg/km | Ampacity at 20℃ (A) | |||||

| Power core | Earth core | Power core | Sheath | MC-0.38/0.66 | MCP-0.38/0.66 | MC-0.38/0.66 | MCP-0.38/0.66 | MC-0.38/0.66 | MCP-0.38/0.66 |

| 3x16 | 1x4 | 1.6 | 4.5 | 31.3~34.4 | 33.2~36.5 | 2070 | 2120 | 85 | 85 |

| 3x25 | 1x6 | 1.8 | 5.5 | 38.4~41.0 | 40.3~44.3 | 2860 | 2930 | 113 | 113 |

| 3x35 | 1x6 | 1.8 | 5.5 | 43.9~48.3 | 45.8~50.4 | 3270 | 3340 | 138 | 138 |

| 3x50 | 1x10 | 2.0 | 5.5 | 47.7~51.0 | 51.5~55.0 | 4260 | 4230 | 170 | 170 |

| MCP-0.66/1.14 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No.of cores x section area (mm²) | Nominal thickness(mm) | Outer diameter of cable(mm) | Weight for reference kg/km | Ampacity at 20℃ (A) | |||||||

| Power core | Earth core A | Earth core B | Power core | Sheath A | Sheath B | Type A | Type B | Type A | Type B | Type A | Type B |

| 3x35 | 1x6 | --- | 2.0 | 6.0 | --- | 47.8~51.0 | --- | 3560 | --- | 150 | --- |

| 3x50 | 1x10 | 3x16/3 | 2.2 | 7.0 | 7.5 | 53.5~58.9 | 59.0~63.0 | 4900 | 4960 | 185 | 185 |

| 3x70 | 1x16 | 3x25/3 | 2.2 | 7.0 | 7.5 | 58.9~63.0 | 63.8~70.2 | 5760 | 5770 | 230 | 230 |

| 3x95 | 1x25 | 3x35/3 | 2.4 | 7.0 | 7.5 | 64.9~71.4 | 68.7~75.6 | 6990 | 6880 | 280 | 280 |

| MCP-1.9/3.3 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No.of cores x section area (mm²) | Nominal thickness(mm) | Outer diameter of cable(mm) | Weight for reference kg/km | Ampacity at 20℃ (A) | |||||||

| Power core | Earth core A | Earth core B | Power core | Sheath A | Sheath B | Type A | Type B | Type A | Type B | Type A | Type B |

| 3x35 | 1x16 | 3x16/3 | 2.8 | 6.0 | 6.0 | 52.1~56.8 | 60.0~63.0 | 4000 | 4245 | 150 | 150 |

| 3x50 | 1x25 | 3x25/3 | 2.8 | 7.0 | 7.5 | 56.4~62.0 | 63.8~70.2 | 5290 | 5320 | 185 | 185 |

| 3x70 | 1x35 | 3x35/3 | 3.0 | 7.0 | 7.5 | 62.7~69.0 | 69.0~75.9 | 6320 | 6370 | 228 | 228 |

| 3x95 | 1x50 | 3x50/3 | 3.0 | 7.0 | 7.5 | 67.8~74.6 | 73.1~78.0 | 7450 | 7350 | 278 | 278 |