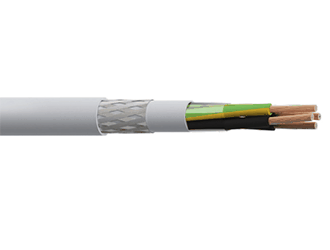

SY PVC GSWB Control Cable

APPLICATION

SY cables are used to control and regulate conveyors, instruments, assembly lines, production lines and similar process automation equipment. It can also regulate the air conditioning system. Process automation is the automatic control of a stage in an industrial process, such as the manufacture of a product.

Control Cable..png)

Parameters

ELECTRICAL CHARACTERISTICS

APPLICATION

SY cables are used to control and regulate conveyors, instruments, assembly lines, production lines and similar process automation equipment. It can also regulate the air conditioning system. Process automation is the automatic control of a stage in an industrial process, such as the manufacture of a product.

Control Cable..png)

| CHARACTERISTICS | CONSTRUCTION | STANDARDS |

| Voltage Rating 300/500V Temperature Rating Fixed: -40°C to +80°C Flexed: -5°C to +70°C Minimum Bending Radius Fixed: 4 x overall diameter Flexed: 12.5 x overall diameter |

Conductor Class 5 flexible plain copper Insulation PVC (Polyvinyl Chloride) Inner Sheath PVC (Polyvinyl Chloride) Armour GSWB (Galvanised Steel Wire Braid) Sheath PVC (Polyvinyl Chloride) Core Identification Black with White number From 3 cores: Black with White number + Green/Yellow Colour-coded cores available upon request Sheath Colour Transparent |

VDE 0207-363-3, VDE 0482-332-1-2, VDE 819-102 (TM54) Flame Retardant according to IEC/EN 60332-1-2 |

| NO. OF CORES |

NOMINAL CROSS SECTIONAL AREA mm2 | NOMINAL THICKNESS OF INSULATION mm | NOMINAL OUTER SHEATH THICKNESS mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

| 2 | 0.75 | 0.40 | 0.8 | 7.2 | 79.3 |

| 2 | 1 | 0.40 | 0.8 | 7.6 | 91 |

| 2 | 1.5 | 0.40 | 0.8 | 8.2 | 110 |

| 2 | 2.5 | 0.50 | 0.8 | 9.4 | 147 |

| 3 | 0.75 | 0.40 | 0.8 | 7.5 | 91.3 |

| 3 | 1 | 0.40 | 0.8 | 7.9 | 104 |

| 3 | 1.5 | 0.40 | 0.8 | 8.6 | 129 |

| 3 | 2.5 | 0.50 | 0.9 | 10.1 | 185 |

| 3 | 4 | 0.60 | 1 | 12 | 269 |

| 3 | 6 | 0.65 | 1.1 | 13.5 | 354 |

| 3 | 10 | 0.75 | 1.3 | 16.9 | 579 |

| 3 | 16 | 0.75 | 1.5 | 19 | 785 |

| 3 | 25 | 0.90 | 1.8 | 23.5 | 1211 |

| 3 | 35 | 0.95 | 2 | 26.7 | 1642 |

| 4 | 0.75 | 0.40 | 0.8 | 8 | 107 |

| 4 | 1 | 0.40 | 0.8 | 8.5 | 124 |

| 4 | 1.5 | 0.40 | 0.8 | 9.2 | 151 |

| 4 | 2.5 | 0.50 | 0.9 | 11.1 | 230 |

| 4 | 4 | 0.60 | 1.1 | 13.2 | 332 |

| 4 | 6 | 0.65 | 1.2 | 14.8 | 442 |

| 4 | 10 | 0.75 | 1.5 | 18.8 | 735 |

| 4 | 16 | 0.75 | 1.6 | 20.9 | 988 |

| 4 | 25 | 0.90 | 2 | 26 | 1536 |

| 4 | 35 | 0.95 | 2.2 | 30 | 2098 |

| 4 | 50 | 1.25 | 2.6 | 35.3 | 2968 |

| 4 | 70 | 1.25 | 3 | 40.5 | 3822 |

| 4 | 95 | 1.60 | 3.6 | 49.4 | 5369 |

| 5 | 0.75 | 0.40 | 0.8 | 8.5 | 120 |

| 5 | 1 | 0.40 | 0.8 | 9.1 | 140 |

| 5 | 1.5 | 0.40 | 0.9 | 10.1 | 182 |

| 5 | 2.5 | 0.50 | 1 | 12.1 | 266 |

| 5 | 4 | 0.60 | 1.1 | 14.2 | 382 |

| 5 | 6 | 0.65 | 1.3 | 16.5 | 525 |

| 5 | 10 | 0.75 | 1.6 | 20.6 | 873 |

| 5 | 16 | 0.75 | 1.8 | 23.4 | 1207 |

| 5 | 25 | 0.90 | 2.2 | 29 | 1875 |

| 5 | 35 | 0.95 | 2.4 | 32.9 | 2577 |

| 7 | 0.75 | 0.40 | 0.8 | 9.1 | 147 |

| 7 | 1 | 0.40 | 0.9 | 9.9 | 181 |

| 7 | 1.5 | 0.40 | 0.9 | 11 | 226 |

| 7 | 2.5 | 0.50 | 1.1 | 13.2 | 338 |

| 12 | 0.75 | 0.40 | 1 | 10.9 | 237 |

| 12 | 1 | 0.40 | 1 | 12.7 | 280 |

| 12 | 1.5 | 0.40 | 1.10 | 14.2 | 365 |

| 12 | 2.5 | 0.40 | 1.20 | 17.5 | 572 |

| 18 | 0.75 | 0.40 | 1.10 | 13.7 | 322 |

| 18 | 1 | 0.40 | 1.20 | 14.9 | 396 |

| 18 | 1.5 | 0.40 | 1.30 | 16.8 | 521 |

| 18 | 2.5 | 0.40 | 1.30 | 20.4 | 809 |

| 25 | 0.75 | 0.40 | 1.30 | 16 | 438 |

| 25 | 1 | 0.40 | 1.40 | 17.6 | 544 |

| 25 | 1.5 | 0.40 | 1.50 | 19.6 | 708 |

| NOMINAL CROSS SECTIONAL AREA mm2 | CURRENT CARRYING CAPACITES 30°C CONTINOUS LOADING A | MAXIMUM RESISTANCE OF CONDUCTOR AT 20°C ohms/km |

| 0.75 | 12 | 26 |

| 1 | 15 | 19.5 |

| 1.5 | 18 | 13.3 |

| 2.5 | 26 | 7.98 |

| 4 | 34 | 4.95 |

| 6 | 44 | 3.3 |

| 10 | 61 | 1.91 |

| 16 | 82 | 1.21 |

| 25 | 108 | 0.78 |

| 35 | 135 | 0.554 |

| 50 | 168 | 0.386 |

| 70 | 207 | 0.272 |

| 95 | 223 | 0.206 |

ControlCable.png)