Fire resistant screened cables 300/500V

We supplies fire performance cables manufactured in accordance with BS7629-1, including the Standard and Enhanced Fire Resistant cable. The Enhanced cable benefits from a mica glass tape offering a further barrier to fire.

Cables covered under BS 7629-1 have the following characteristics:

| Thermosetting insulation with a voltage rating of 300/500V |

| Resistance to fire (Circuit integrity) |

| Emit limited amounts of smoke and corrosive gases in the event of fire |

| Intended for use in emergency lighting, fire detection and fire alarm system circuits |

BS7629-1 Cable Construction

| Multicore cables | Multipair cables | |

| Uninsulated conductors | Tinned annealed copper (Class 1 or 2) | Tinned annealed copper (Class 1,2 or 5) |

| Insulated conductors | Plain or tinned annealed copper (Class 1 or 2) | Plain or tinned annealed copper (Class 1, 2 or 5) |

| Drain wire | One or more tinned annealed copper wires | |

| Insulation | Type EI 2, Type EI 3, Type EI 5, GP4 or GP6 | |

| Screen | Metallic or laminated metallic tape | |

| Sheath | LTS 3 compound | |

BS 7629-1 is a British Standard that pertains to fire performance cables. Specifically, it covers the requirements and test methods for electric cables intended for use in emergency circuits, control circuits, and essential systems such as fire alarms, emergency lighting, and smoke extraction. The standard is part of the broader set of standards addressing fire-resistant and fire performance cables. These cables are designed for applications where maintaining circuit integrity during a fire is crucial.

These cables are particularly relevant to installations where fire resistance is essential, ensuring that critical circuits continue to function during a fire incident. Emergency and safety systems, such as those mentioned earlier, rely on these types of cables to maintain their functionality when needed most.

Multicore circular cables can be of 2-core, 3-core or 4-core construction with uninsulated circuit protective conductor, and of 7-core, 12-core, 19-core, 2-pair and 3-pair construction with uninsulated tinned annealed copper drain conductor of not less than 0.5mm2. All cables in this standard include a metallic layer, which provides electrostatic screening.

Additionally, copper conductor cables manufactured to BS7629-1 have a Low Smoke Zero Halogen (LSZH) insulation and sheathing that meets the standard of BS EN 60754 which specifies that the level of hydrochloric gases emitted during fire may not be greater than 0.5%. Complete cable tests include Smoke emission to BS EN 61034-2 , Flame propagation to BS EN 60332-1-2 , fire resistance to BS EN 50200 and BS 6387, categories C, W, Z.

BS7629-1 cable resistance to fire, mechanical shock and water

This Standard specifies that the cable must have a minimum duration of survival of 30 minutes (PH30). They must resist fire and impact alone for 15 minutes, followed by 15 minutes of fire, impact and water.

CHARACTERISTICS

Voltage Rating Uo/U

300/500V

Temperature Rating

-40°C to +90°C

Minimum Bending Radius

6 x overall diameter

CONSTRUCTION

Conductor

1.5mm2 - 2.5mm2 : Class 1 solid Copper

4mm2 and over: Class 2 stranded Copper

Insulation

High performance fire resistant silicone rubber

Overall Screen

Al/PET (Aluminium/Polyester Tape)

Circuit Protective Conductor

Tinned copper

Outer Sheath

LSZH (Low Smoke Zero Halogen)

Core Identification

2 cores: Blue Brown + Bare Earth

3 cores: Brown Black Grey + Bare Earth

4 cores: Blue Brown Black Grey

Sheath Colour

Red White

DIMENSIONS

BS7629-1 Standard Fire Resistant CableClass 1 Solid Plain Conductor

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm2 | EARTH WIRE CONSTRUCTION n° /mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

| 2 | 1.5 | 1/1.38 | 8 | 95 |

| 2 | 2.5 | 1/1.75 | 9.4 | 130 |

| 2 | 4 | 7/0.85 | 11.5 | 200 |

| 3 | 1.5 | 1/1.38 | 8.5 | 115 |

| 3 | 2.5 | 1/1.75 | 10 | 170 |

| 3 | 4 | 7/0.85 | 12.2 | 260 |

| 4 | 1.5 | 1/1.38 | 9.4 | 140 |

| 4 | 2.5 | 1/1.75 | 11 | 210 |

| 4 | 4 | 7/0.85 | 13.5 | 330 |

BS7629-1 Enhanced Fire Resistant Cable

Class 1 Solid Plain Conductor

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm2 | EARTH WIRE CONSTRUCTION n° /mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

| 2 | 1.5 | 1/1.18 | 8.8 | 105 |

| 2 | 2.5 | 1/1.75 | 10.2 | 150 |

| 2 | 4 | 7/0.85 | 12.2 | 220 |

| 3 | 1.5 | 1/1.38 | 9.3 | 130 |

| 3 | 2.5 | 1/1.75 | 10.8 | 190 |

| 3 | 4 | 7/0.85 | 13 | 280 |

| 4 | 1.5 | 1/1.38 | 10.3 | 165 |

| 4 | 2.5 | 1/1.38 | 12 | 240 |

| 4 | 4 | 7/0.85 | 14.4 | 350 |

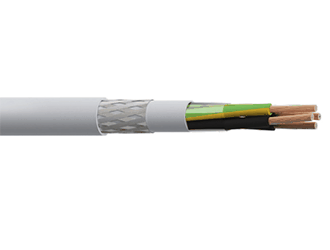

ControlCable.png)