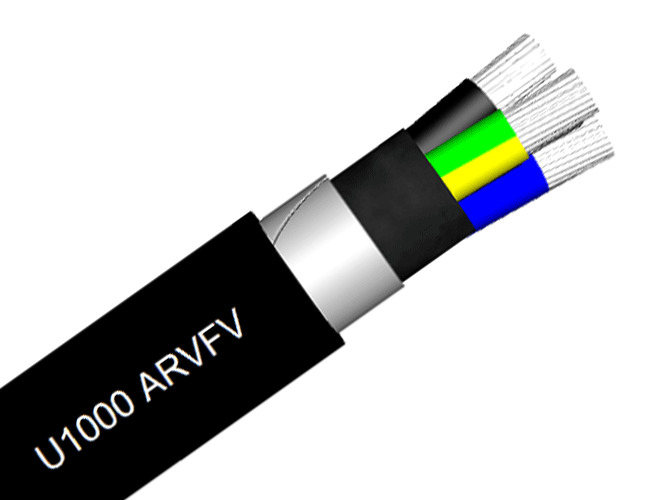

With a sheath and armor, U-1000 ARVFV is an enhanced version of the cables and U-1000 AR2V. They can be used in all industrial installations requiring mechanical protection. These cables can be provided in hard and SH C1 (NF C 32-323) and HR (resistant to aliphatic hydrocarbons). The design and characteristics of the materials comply with IEC 60502-1.

U-1000 ARVFV Cable Typical Applications

Power Distribution in Industrial and Commercial Sites

Used in low-voltage networks (0.6/1kV) for power supply to equipment, machinery, lighting, and control systems.

Direct Burial and Harsh Environments

The steel wire armor (F) provides high mechanical protection, making it suitable for direct burial and outdoor installation, even in areas with risk of mechanical damage.

Infrastructure and Construction Projects

Commonly installed in tunnels, basements, public buildings, and underground networks requiring extra mechanical strength.

Cable Trays, Ducts, and Trenches

Suitable for laying in ducts, cable trays, and concrete trenches.

Underground and Outdoor Installations

UV-resistant and water-resistant for outdoor or underground use.

U-1000 ARVFV Cable Advantages

Cost-saving

The conductors of the U-1000 ARVFV are made of aluminium. An aluminium cable is 20% to 50% less expensive than its copper variant, without reducing its quality and lifespan.

Lightweight / Aluminium

This cable is lightweight because the conductors of the U-1000 ARVFV are made of aluminium. Compared to a similar cable with copper conductors it can weigh up to 50% less. First of all, this is ideal during installation, installing the cable will be easier and more efficient. Secondly, a lightweight cable reduces transport costs and decreases the weight put on supporting and load-bearing constructions.

Double Steel Tape Armour (DSTA)

The interior of the cable is completely sealed because of a double layer of galvanized steel tape. The second layer of tape covers the seams of the first layer of tape. This protects the U-1000 ARVFV from sharp objects. Another advantage is that the armouring serves as a shield against electromagnetic fields.

UV resistant

Cables that are not UV resistant will be affected when they are exposed to direct sunlight. The U-1000 ARVFV is UV resistant and can therefore be used above ground in the open air. The outer sheath of the cable will not be harmed by the ultra-violet light which normally dries out a cable or causes cracks or bursts in the sheath. This will preserve the functionality of the cable.

Flame retardant

Cables used to be responsible for spreading fire. The U-1000 ARVFV is flame retardant. This means that this cable is designed in a way that it will not spread fire. Cables with these advantages are often used in buildings and at locations where people live, work and travel / move.

U-1000 ARVFV Cable Standards

XP C 32-322

NF C 32-323

IEC 60502-1

U-1000 ARVFV Cable Construction

Aluminum conductorStrands to IEC 60228 class 2

XLPE insulation according to XP C 32-321

Color codes to HD 308 S2(XP C32-321)

Not fibrous and not hygroscopic filler(only for multicore cables)

PVC inner jacket

Two steel tapes helically wraped armour

Flexible black PVC outer jacket

U-1000 ARVFV Cable Technical Characteristics

Working Voltage : 600/1000 voltsTest voltage : 3500 volts

Minimum bending radius : 10 x Ø

Operation temperature rage : -15 °C to 90 °C

Short-circuit temperature : 250 °C

Flame retardant : EN 60332-1/NF C 32-070 C2

U-1000 ARVFV Cable Parameter

| AWG | Cross Section | Insulation Thickness | Amour Thickness | Minimum Sheath Thickness | Approx. Overall Diameter | Approx. Cable Weight |

| mm² | mm | mm | mm | mm | kg/km | |

| 8 | 2x10 | 0.7 | 0.2 | 1.4 | 18.5 | 420 |

| 6 | 2x16 | 0.7 | 0.2 | 1.5 | 20.5 | 540 |

| 4 | 2x25 | 0.9 | 0.2 | 1.6 | 24.5 | 760 |

| 2 | 2x35 | 0.9 | 0.2 | 1.7 | 27 | 930 |

| 8 | 3x10 | 0.7 | 0.2 | 1.5 | 19 | 470 |

| 6 | 3x16 | 0.7 | 0.2 | 1.5 | 22 | 590 |

| 4 | 3x25 | 0.9 | 0.2 | 1.6 | 26 | 830 |

| 2 | 3x35 | 0.9 | 0.2 | 1.7 | 29 | 1030 |

| 1 | 3x50 | 0.9 | 0.2 | 1.8 | 32.5 | 1290 |

| 2/0 | 3x70 | 1.1 | 0.2 | 2 | 37.5 | 1710 |

| 3/0 | 3x95 | 1.1 | 0.5 | 2.1 | 43.5 | 2610 |

| 4/0 | 3x120 | 1.2 | 0.5 | 2.3 | 47.5 | 3110 |

| 300MCM | 3x150 | 1.4 | 0.5 | 2.4 | 53 | 3770 |

| 500MCM | 3x185 | 1.6 | 0.5 | 2.5 | 58 | 4540 |

| 750MCM | 3x240 | 1.7 | 0.5 | 2.7 | 65.5 | 5620 |

| - | 3x300 | 1.8 | 0.5 | 2.9 | 72 | 6830 |

| 1 | 3x50+35 | 1.0/09 | 0.2 | 1.9 | 34.5 | 1500 |

| 2/0 | 3x70+50 | 1.1/0.9 | 0.2 | 2 | 40 | 2000 |

| 3/0 | 3x95+50 | 1.1/1.0 | 0.5 | 2.2 | 45 | 2870 |

| 4/0 | 3x120+70 | 1.2/1.1 | 0.5 | 2.3 | 50 | 3460 |

| 300MCM | 3x150+70 | 1.4/1.1 | 0.5 | 2.5 | 54 | 4090 |

| 500MCM | 3x185+70 | 1.6/1.1 | 0.5 | 2.6 | 59 | 4980 |

| 750MCM | 3x240+95 | 1.7/1.1 | 0.5 | 2.8 | 66 | 6210 |

| 8 | 4x10 | 0.7 | 0.2 | 1.5 | 20.5 | 540 |

| 6 | 4x16 | 0.7 | 0.2 | 1.6 | 23.5 | 700 |

| 4 | 4x25 | 0.9 | 0.2 | 1.7 | 28 | 1000 |

| 2 | 4x35 | 0.9 | 0.2 | 1.8 | 31.5 | 1230 |

| 1 | 4x50 | 1 | 0.2 | 1.9 | 35.5 | 1550 |

| 2/0 | 4x70 | 1.1 | 0.5 | 2.1 | 42.5 | 2490 |

| 3/0 | 4x95 | 1.1 | 0.5 | 2.3 | 47.5 | 3120 |

| 4/0 | 4x120 | 1.2 | 0.5 | 2.4 | 53 | 3780 |

| 300MCM | 4x150 | 1.4 | 0.5 | 2.6 | 58.5 | 4550 |

| 500MCM | 4x185 | 1.6 | 0.5 | 2.7 | 64.5 | 5490 |

| 750MCM | 4x240 | 1.7 | 0.5 | 2.9 | 72.5 | 6860 |

| - | 4x300 | 1.8 | 0.5 | 3.1 | 79.5 | 8250 |

| 8 | 5x10 | 0.7 | 0.2 | 1.6 | 22.5 | 640 |

| 6 | 5x16 | 0.7 | 0.2 | 1.8 | 26 | 820 |

| 4 | 5x25 | 0.9 | 0.2 | 1.8 | 31 | 1190 |