APPLICATION

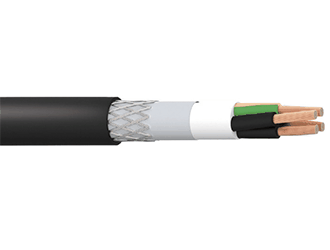

Used as interconnecting cable for measuring, controlling or regulation in control equipment for assembly and production lines, conveyors and for computer units. Suitable for flexible use in conditions of light mechanical stress. Can be used outdoors when protected against direct sunlight, and in dry or moist conditions indoors. The braided screen offers mechanical protection and a level of electro-magnetic shielding. The galvanized coating helps protect against corrosion. For installations where fire, smoke emissions and toxic fumes create a potential risk to life and equipment.

DIMENSIONS

CONDUCTORS

Class 2 Stranded Conductors for Single Core and Multi-Core Cables

The above table is in accordance with BS EN 60228 (previously BS 6360)

ELECTRICAL CHARACTERISTICS

Current Carrying Capacity at 30ºC

VOLTAGE DROP

DE-RATING FACTORS

Used as interconnecting cable for measuring, controlling or regulation in control equipment for assembly and production lines, conveyors and for computer units. Suitable for flexible use in conditions of light mechanical stress. Can be used outdoors when protected against direct sunlight, and in dry or moist conditions indoors. The braided screen offers mechanical protection and a level of electro-magnetic shielding. The galvanized coating helps protect against corrosion. For installations where fire, smoke emissions and toxic fumes create a potential risk to life and equipment.

| CHARACTERISTICS | CONSTRUCTION | STANDARDS |

| Voltage Rating (Uo/U) 300/500V Temperature Rating -15ºC to +70°C Minimum Bending Radius 10 x overall diameter |

Conductor Class 5 flexible copper conductor Insulation LSZH (Low Smoke Zero Halogen) Type TI6 Bedding LSZH (Low Smoke Zero Halogen) Type TM7 Braiding GSWB (Galvanized Steel Wire Braid) minimum coverage of braiding shall be 50% Sheath LSZH (Low Smoke Zero Halogen) Type TM7 Core Identification 2 core: Blue Brown 3 core: Blue Brown Green/Yellow 4 core: Brown Black Grey Green/Yellow 5 core: Blue Brown Black Grey Green/Yellow Sheath Colour Black Note SY Cables are not suitable for direct connection into the main |

Flame Retardant according to IEC/EN 60332-1-2, IEC/EN 60332-3-24 Low Smoke Zero Halogen according to IEC/EN 61034-1 Determination of halogen acid gas content: IEC/EN 60574-1 Determination of acidity and conductivity: IEC/EN 60574-2 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm2 | NOMINAL THICKNESS OF INSULATION mm | NOMINAL THICKNESS OF BEDDING mm | NOMINAL DIAMETER OF GSWB mm | NOMINAL DIAMETER OF SHEATH mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

| 2 | 1.5 | 0.5 | 0.5 | 0.24 | 0.8 | 8 | 109 |

| 3 | 1 | 0.5 | 0.5 | 0.24 | 1 | 8 | 114 |

| 3 | 1.5 | 0.5 | 0.5 | 0.24 | 1 | 9 | 138 |

| 3 | 2.5 | 0.6 | 0.5 | 0.24 | 1 | 10 | 188 |

| 3 | 4 | 0.6 | 0.6 | 0.24 | 1 | 12 | 256 |

| 3 | 6 | 0.7 | 0.6 | 0.24 | 1.1 | 14 | 352 |

| 4 | 1.5 | 0.5 | 0.5 | 0.24 | 1 | 10 | 161 |

| 4 | 2.5 | 0.6 | 0.5 | 0.24 | 1 | 11 | 223 |

| 4 | 4 | 0.6 | 0.6 | 0.24 | 1 | 13 | 310 |

| 4 | 6 | 0.7 | 0.6 | 0.24 | 1.1 | 15 | 430 |

| 5 | 1.5 | 0.5 | 0.5 | 0.24 | 1 | 10 | 189 |

| 5 | 2.5 | 0.6 | 0.6 | 0.24 | 1 | 12 | 264 |

| 5 | 6 | 0.7 | 0.6 | 0.24 | 1.2 | 16 | 523 |

| 5 | 10 | 0.8 | 0.8 | 0.3 | 1.2 | 20 | 822 |

| 5 | 16 | 0.9 | 0.8 | 0.3 | 1.4 | 24 | 1217 |

Class 2 Stranded Conductors for Single Core and Multi-Core Cables

| NOMINAL CROSS SECTIONAL AREA mm2 | MAXIMUM DIAMETER OF WIRES IN CONDUCTOR mm | MAXIMUM RESISTANCE OF CONDUCTOR AT 20ºC ohms/km |

| Plain Wires | ||

| 1 | 0.21 | 19.5 |

| 1.5 | 0.26 | 13.3 |

| 2.5 | 0.26 | 7.98 |

| 4 | 0.31 | 4.95 |

| 6 | 0.31 | 3.3 |

| 10 | 0.41 | 1.91 |

| 16 | 0.41 | 1.21 |

ELECTRICAL CHARACTERISTICS

Current Carrying Capacity at 30ºC

| NOMINAL CROSS SECTIONAL AREA mm2 | CURRENT CARRYING CAPACITY Amps | |

| In Conduit | In Air | |

| 1 | 12 | 20 |

| 1.5 | 15 | 24 |

| 2.5 | 20 | 32 |

| 4 | 25 | 42 |

| 6 | 33 | 54 |

| NOMINAL CROSS SECTIONAL AREA mm2 | TWO CORE CABLE DC mV/A/m | SINGLE-PHASE TWO CORE CABLE AC mV/A/m | THREE-PHASE THREE OR FOUR CORE CABLE AC mV/A/m |

| 1 | 44 | 44 | 38 |

| 1.5 | 29 | 29 | 25 |

| 2.5 | 18 | 18 | 15 |

| 4 | 11 | 11 | 9.5 |

| 6 | 7.3 | 7.3 | 6.4 |

| 10 | 4.4 | 4.4 | 3.8 |

| 16 | 2.8 | 2.8 | 2.4 |

| NO. OF CORES | 5 | 7 | 10 | 14 | 19 | 24 | 44 | 48 |

| DE-RATING FACTOR | 0.72 | 0.63 | 0.56 | 0.51 | 0.45 | 0.42 | 0.34 | 0.33 |

ControlCable.png)

ControlCable.png)